What Are the Usual Kinds of PCBA Substratums?

Table of Conent

Table of Conent

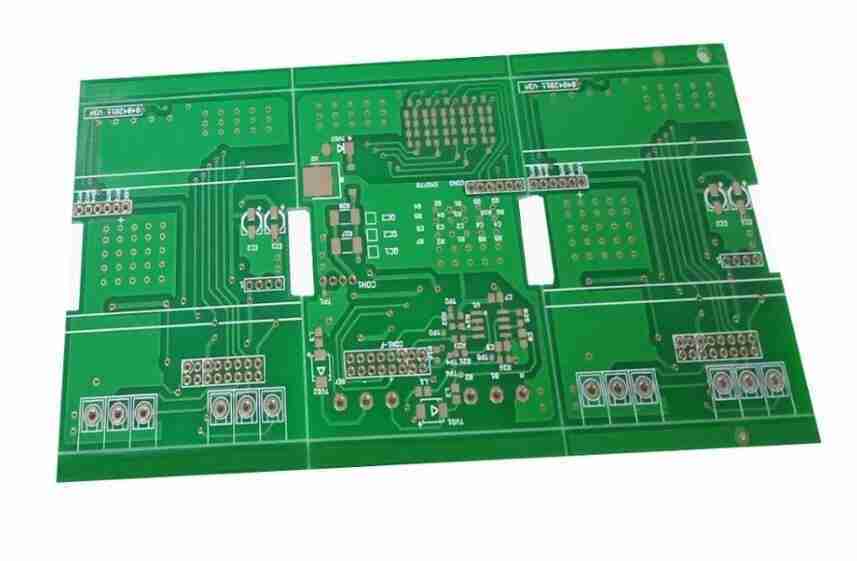

When we are facing electronic products, the PCBA board is a really vital part. The board has various kinds, and the characteristics and uses these types are also various. This write-up defines the common types and requirements of PCBA substrates.

1.FR4 substratum

FR4 substrate is a very usual sort of veneer in PCBA handling plants. It is a fiberglass-reinforced plastic material typically used in high-frequency and high-speed electronic circuits. FR4 substrate has good mechanical strength and high-temperature resistance, so it is commonly utilized in the style and production procedure of PCB boards. Its insulation performance is likewise exceptional and typically can satisfy the need for high degrees of integrity.

The general density of FR4 is usually 0.4 mm, 0.6 mm, 0.8 mm, and 1.0 mm, and so on, and FR4 plates of these thicknesses appropriate for various events. In general, the thicker the FR4 board, the higher its mechanical stamina, and the thicker board will certainly be a lot more steady in terms of electric residential properties.

2.Aluminum substratum

The aluminum substrate in PCBA production is defined by warmth dissipation, electricity transmission, corrosion resistance, inexpensive, excellent processability, and more. It is one of the most generally used in LED lighting, high power, high frequency, and other circuit card. Among them, the LED lighting circuit card is primarily since the heat of LED is reasonably high, warmth dissipation is required to decrease the temperature, and the aluminum substrate has excellent warmth dissipation performance in this regard.

The density of the light weight aluminum substrate is normally 1.0 mm, 1.2 mm, 1.5 mm, etc. In a circuit board with big warm output, the light weight aluminum substrate is an excellent choice, which can make certain the long-lasting operation and stability of the motherboard.

3.FR1 substrate

The FR1 substratum in PCBA makers is a cheaper substratum than FR4, however its electrical properties and mechanical stamina are lower. As a result, it is normally only used for low-end PCB circuit card style and production.

Its basic density is 1.0 mm, 1.2 mm, etc. In family member terms, the manufacturing price of FR1 is reduced, and it is a fairly affordable selection.

4.High-frequency board

A High-frequency plate is extremely unique. Because it has exceptional qualities for the transmission of signals, it is very suitable for use in high-frequency circuit design.

High-frequency boards are commonly in use in RF circuits, microwave circuits, antenna circuits, and comparable circuit applications. Its basic density is typically between 0.2 mm and 0.8 mm, and compared with various other board kinds, the cost of high-frequency boards is greater, however its digital efficiency is superb, and the marketplace demand is also large.

In recap:

In the PCBA layout and production procedure, the choice of substratum is really vital. Different substrate types are suitable for different applications and ought to be picked according to actual needs. FR4 board considers both electrical residential or commercial properties and mechanical strength, is a general substratum type, and the aluminum substrate has superior performance in regards to heat dissipation. The high-frequency board is suitable for motherboard that call for high-frequency transmission applications, yet its expense is also relatively high contrasted to other plates.

Latest Blog

Contact Info

Phone: +86-755-82882936

Email: [email protected]

WhatsApp: +86-13570802455

Wechat: +86-13570802455

Address: 2nd floor,D Bldg.,Electric Link Technology Bldg.,Gongming,Guangming New Dist.,518106 Shenzhen, China