What’s the Highest Temperature Can PCB Fr4 Withstand and What Are the Heat Dissipation Considerations?

Table of Conent

Table of Conent

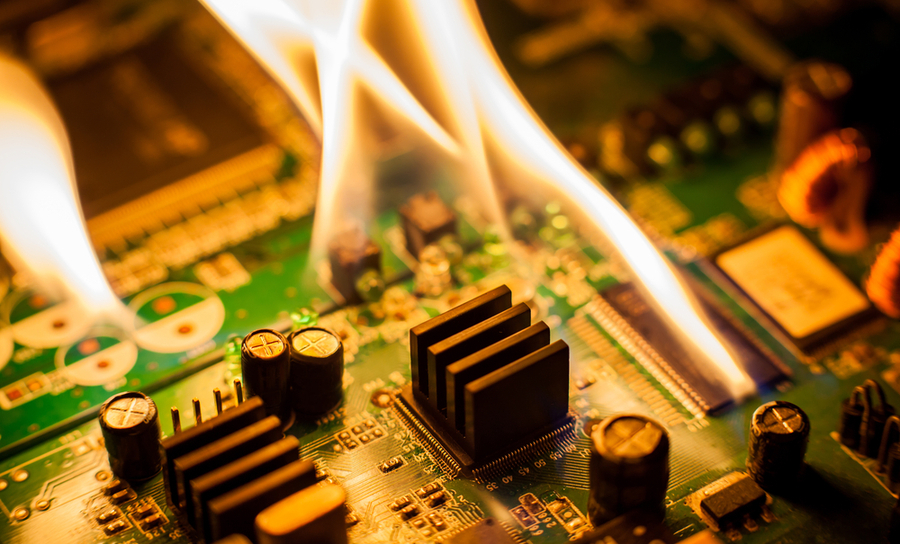

In PCB design, the same oversight of the temperature requirements of PCBs will cost you more than balloons and ice cream. You need to know how much heat your PCB can withstand before it starts to suffer structural damage, especially if it is deployed in a high-temperature environment.

What is the maximum temperature of FR4 PCBs?

As you know, FR4 indicates the rating of the flame-retardant F4 property of the PCB. FR4 PCBs are made of multiple layers of fiberglass epoxy laminate. FR4 PCBs are preferred among manufacturers because of their consistent physical properties.

FR4 PCBs are very strong when exposed to high temperatures, but at a certain temperature, their physical properties change. The heat-resistant properties of FR4 are indicated by the Tg, or glass transition temperature, at which it changes from a solid state to a soft and rubbery state. Typically, FR4 PCBs are rated for a Tg of 130°C.

In other words, if a PCB rated at 130°C is heated above its glass transition temperature, it will lose its solid form. Not only will your mechanical structure be unstable, but the electrical properties of the PCB will also degrade when the rated Tg is exceeded. That’s why it’s important to consider the importance of fr4 maximum temperature when designing PCBs for applications such as oil and gas and automotive where temperatures exceed typical Tg values.

Medium-High TG-PCBs: Beyond Typical FR4 Maximum Temperatures

If the application requires a PCB with a higher Tg value, you’ll need to choose a medium or high Tg PCB. Medium Tg PCBs typically have a maximum temperature of over 150°C, while high Tg PCBs are rated for over 170°C. PCBs with higher Tg values also have better moisture and chemical resistance, as well as a more robust physical structure under thermal conditions.

Unless otherwise specified, manufacturers will use low Tg PCBs for manufacturing. Medium-high Tg PCBs are generally more expensive. High Tg PCBs are usually produced using materials such as S1141 and S1002-M. The lamination of high Tg PCBs involves a lot of heat due to the higher glass transition temperature. Price-wise, high TG PCBs are more expensive.

Some applications require high Tg PCBs

Important Considerations When Using FR4 at Maximum Temperatures

A common mistake is to use the TG value to determine the operating temperature of a PCB. When selecting the right FR4 PCB, you should always allocate at least a 20°C margin. For example, a lower Tg FR4 of 130°C should have an operating temperature limit of 110°C.

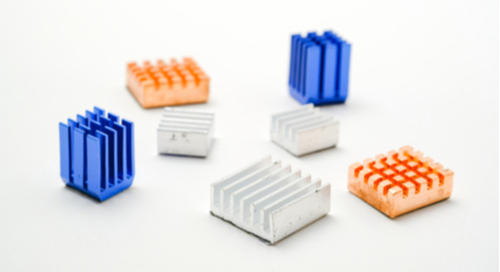

As a PCB designer, you need to be aware of thermal regulation techniques in your design. Power regulation modules generate heat and proper heat dissipation techniques should be employed. Employing heat sinks or thermal vias can help prevent hot spots from overheating, which can cause the PCB’s temperature to exceed its limits.

Tg ratings and the operating temperature of a PCB are not the only factors that determine its functionality in high-temperature environments. The operating temperature limits of individual components must also be considered in the design.

Heat sinks help regulate heat dissipation

For example, military-grade, automotive-grade, and extended-temperature components have wider temperature tolerances than commercial-grade or consumer-grade components. While components with higher temperature tolerances are expensive, they are essential to ensuring the reliability of PCB circuits in the field.

For microcontrollers, it should be noted that reducing their system clocks will generally increase their maximum operating temperature limits.

To optimize the design and avoid FR4 maximum temperatures, it helps to use a reliable, flexible design and analysis software with thermal analysis capabilities, such as Cadence’s. Especially if you are looking for a layout package with customizable vias, net management, and proper analysis capabilities, then OrCAD is the way to go.

Latest Blog

Contact Info

Phone: +86-755-82882936

Email: [email protected]

WhatsApp: +86-13570802455

Wechat: +86-13570802455

Address: 2nd floor,D Bldg.,Electric Link Technology Bldg.,Gongming,Guangming New Dist.,518106 Shenzhen, China