PCBA processing plants need to know three welding technologies

Table of Conent

Table of Conent

During my electronics career, I have been exposed to and used many welding techniques. Initially, I relied mainly on welding irons for welding work. Almost all welding tasks can be completed with a welding iron. However, in certain situations, it is more convenient to use other welding techniques.

Therefore, this article will explore several different welding techniques.

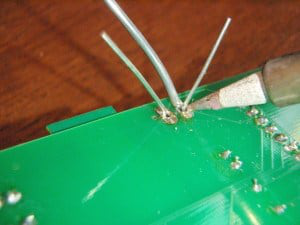

1. Welding Iron

This is a basic welding method that uses a welding iron to heat the pins and pads of the component and then apply welding to complete the welding process.

2. Use reflow welding

You may have already mastered the technique of this operation, but what if you still have doubts: about how to weld?

Let’s explore the reflow welding technique. In short, reflow welding involves placing the circuit board in an oven to bake. This process is similar to baking bread, although I don’t recommend it. You don’t need professional equipment to do this, you can even use a home toaster.

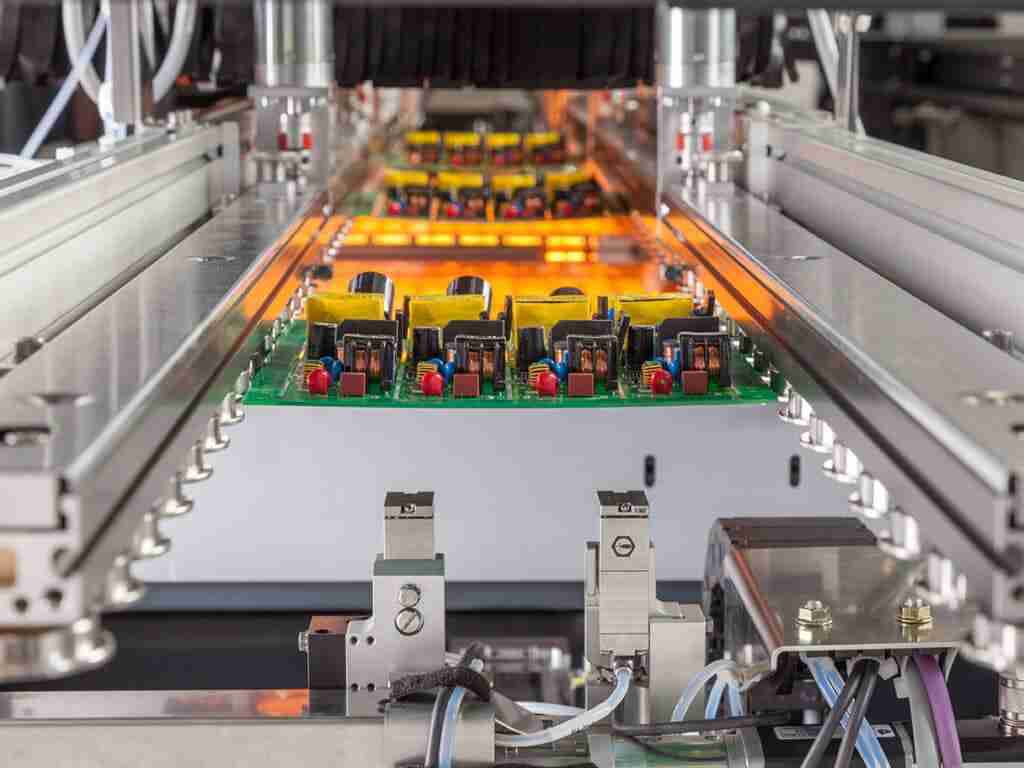

The rapid welding of surface mount components is a widely used technique. First, welding paste is applied to the pad by the printer. Solder paste is a special form of welding. Next, the surface mount components (SMT) are mounted on the circuit board and welded in a reflow oven with ten temperature zones.

During the reflow welding, the circuit board is heated to a certain temperature to melt the welding. After that, the board is cooled, and the welding solidifies. If done correctly, a uniform welding joint will be formed across the entire board.

A significant advantage of reflow welding technology is that the components tend to position themselves. This is particularly beneficial for welding integrated circuits with small lead pitches. For example, if the integrated circuit is not perfectly aligned with the pads, it will usually slide automatically into the correct position when the welding melts.

3. Hot air welding

Hot air welding is a way of melting welding by blowing hot air to a specific area of the circuit board.

Hot air welding requires a hot air welding station, which looks similar to a welding iron but works by blowing hot air rather than direct heating. This technology is particularly applicable in circuit board rework and can effectively repair errors in the welding process.

Shenzhen Assypcb SMT Processing: Removing chips one by one is a tedious task. However, with hot air welding, the welding on all pins of the chip can be melted at the same time, making it easier to move the chip to the correct position.

Latest Blog

Contact Info

Phone: +86-755-82882936

Email: [email protected]

WhatsApp: +86-13570802455

Wechat: +86-13570802455

Address: 2nd floor,D Bldg.,Electric Link Technology Bldg.,Gongming,Guangming New Dist.,518106 Shenzhen, China