PIP Through-Hole Reflow Technology

Table of Conent

Table of Conent

PIP technology is a method of assembling through-hole components using a standard reflow welding process. This process is also called THTR (Through-hole Technology Reflow). In most printed circuit boards (PCBs) containing surface mount components (SMDs), some through-hole components such as connectors, switches, capacitors, etc. are usually integrated. The core of PIP technology is that it uses surface-mount welding to fix through-hole components in holes (PTH) and reflow the welding process together with other surface-mount components. For electronic developers who assemble their prototypes, PIP technology may be an attractive option.

The figure below shows the processing order we recommend:

The hole and pin diameters, board thickness, stencil thickness, opening size, and the paste printing technique and paste type used are critical parameters in this process. That can withstand the reflow welding temperature can be welded using this method. Most data sheets provided for PIP connectors also contain useful information, such as stencil design recommendations.

Based on our practical experience, the following suggestions can help achieve the best welding results:

· Keep the hole diameter as small as possible to facilitate welding component pins;

· Avoid forming large annular pads;

· Do not place through holes in the area where welding paste is to be printed;

· Hold the squeegee at a 45-degree angle to the stencil to optimize the paste pressure;

· Enlarge the stencil aperture to cover the area around the PTH hole (i.e. overprint) so that the welding paste can flow smoothly into the hole when it melts.

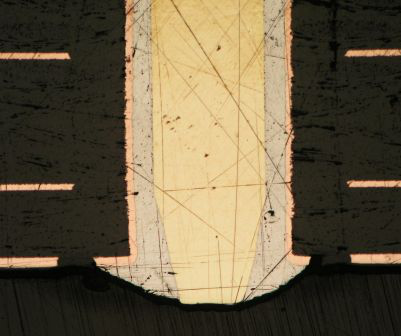

Image of the exposed bottom of the PCB after printing flux on the top:

The advantages of PIP technology are as follows:

· You can skip a step in the assembly process, Reducing production costs and saving time.

· All components can be processed in a single SMT welding process.

· Its excellent wetting performance significantly reduces the risk of welding bridges.

· Connectors suitable for PIP usually take up less circuit board space and are easier to repair than SMT connectors.

Shenzhen Assypcb SMT: Pasting technology is very practical because it can help you save time and human resources. We firmly believe that this technology makes it easier for electronic developers to assemble prototypes in-house in a reliable, fast, and economical way.

Latest Blog

Contact Info

Phone: +86-755-82882936

Email: [email protected]

WhatsApp: +86-13570802455

Wechat: +86-13570802455

Address: 2nd floor,D Bldg.,Electric Link Technology Bldg.,Gongming,Guangming New Dist.,518106 Shenzhen, China