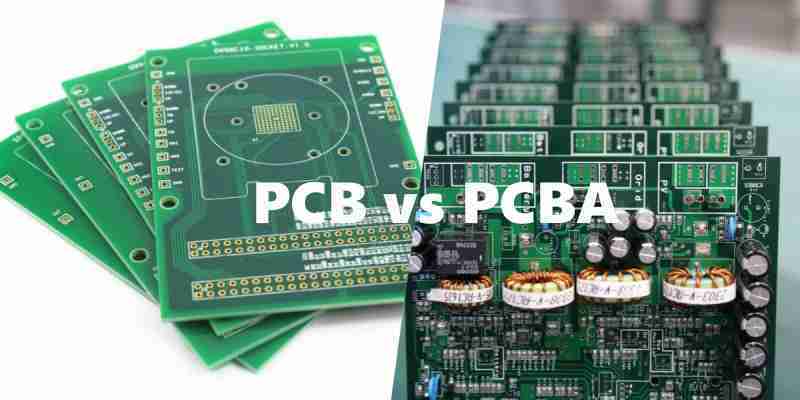

PCB VS PCBA

Table of Conent

Table of Conent

With the rapid development of electronic information technology, I believe many people have heard of the two professional terms “PCB” and “PCBA” and are not unfamiliar with them. After an in-depth discussion, we found that although PCB and PCBA differ by only one letter, the concepts they represent significantly differ.

So, what is the connection between PCB and PCBA? What are the differences between them? This article will give readers an in-depth understanding of these two concepts and help them fully grasp the differences between PCB and PCBA.

About PCB

PCB, the abbreviation of Printed Circuit Board, means printed circuit board in Chinese. It is called a “printed” circuit board because it is made using electronic printing technology. PCB plays a vital role in the electronics industry. It is the carrying platform for electronic components and the medium for electrical connection between electronic components.

PCB is mainly composed of epoxy glass resin material, and according to the number of signal layers, it can be divided into four-layer boards, six-layer boards, and eight-layer boards. Among them, four-layer boards and six-layer boards are more commonly used. SMD components such as chips are installed on the PCB.

The reason why PCB is widely used in the production and manufacturing of electronic products is that it has the following characteristics and advantages:

1. High wiring density, compact size, and light weight contribute to the miniaturization of electronic devices.

2. The repeatability and consistency of graphics reduce errors during wiring and assembly, thereby saving time required for equipment maintenance, debugging, and inspection.

3. It facilitates mechanized and automated production, improves production efficiency, and reduces the cost of electronic equipment.

4. The design can be standardized to facilitate the interchangeable use of components.

About PCBA

PCBA, short for Printed Circuit Board Assembly, refers to the complete production process of assembling components through printed circuit board (PCB) blank surface mount technology (SMT) and dual in-line package (DIP) plug-ins. In short, PCBA covers the entire manufacturing process from assembling components on the PCB blank board through SMT technology to plug-in through DIP technology.

It should be noted that both SMT and DIP are technologies for integrating electronic components on PCB boards, but there are significant differences between them. SMT technology does not require drilling holes in the PCB board but attaches micro-components to the surface of the PCB board through a placement machine. Its production process includes PCB board positioning, solder paste printing, placement machine placement, reflow soldering, and finished product inspection. In contrast, DIP technology, that is, dual in-line packaging, is suitable for components that are larger and not suitable for mounting technology. The production process includes adhesive application, plug-in, inspection, wave soldering, cleaning, and finished product inspection.

PCB VS PCBA

To sum up, PCBA generally refers to a processing process, and can also be understood as a finished circuit board. That is, only after all the processes on the PCB board are completed can it be called PCBA. PCB refers to a printed circuit board without any components installed. In short, PCB refers to a circuit board without components; PCBA refers to a circuit board assembled through the SMT process, DIP plug-in, and other processes. There are no components attached to the standard PCB, which is often called a “Printed Wiring Board (PWB)”. After PCB is processed by SMTing or DIP welding, it becomes PCBA (Printed Circuit Board + Assembly).

It is worth noting that with the advancement of packaging technology, the industry has put forward new requirements for printed circuit boards (PCBs) to adapt to the needs of high-density packaging and high speed. In the past, when electronic product manufacturers completed the production of a complete circuit board, they usually needed to purchase the PCB first and then contact the chip manufacturer for processing. This process was cumbersome and costly. Nowadays, many manufacturers prefer to choose PCB manufacturers to process patches while producing PCBs or have patch manufacturers purchase PCBs instead. Both methods simplify the process and improve production efficiency.

Assypcb was established to meet this demand. Assypcb is committed to providing high-quality and fast services, providing electronic product manufacturers with PCB prototyping/small batch production, SMT & DIP welding, material procurement, and other PCBA one-stop professional technical services. PCB procurement and SMT chip processing are two different production methods, and many electronic manufacturers only specialize in one of them. Therefore, when choosing a PCBA processing manufacturer, electronic product manufacturers need to comprehensively consider the strength of the manufacturer and choose a manufacturer that is experienced and can efficiently complete the entire processing process.

Latest Blog

Contact Info

Phone: +86-755-82882936

Email: [email protected]

WhatsApp: +86-13570802455

Wechat: +86-13570802455

Address: 2nd floor,D Bldg.,Electric Link Technology Bldg.,Gongming,Guangming New Dist.,518106 Shenzhen, China