A Complete Guide to Rigid Flex PCB

Table of Conent

Table of Conent

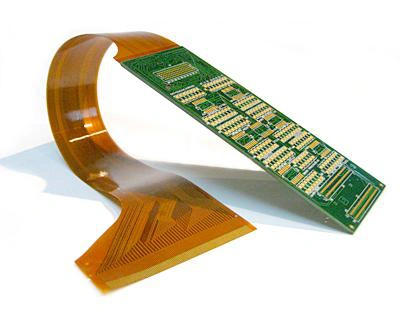

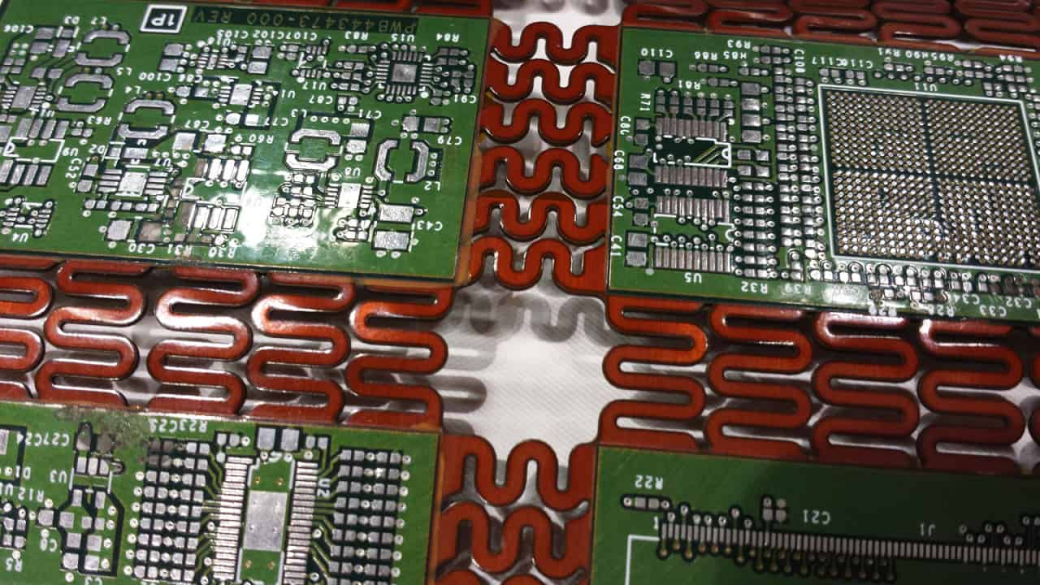

We want our devices to fold, twist, and curve, but we still expect them to be rock-solid and reliable. That’s the challenge.Enter the rigid flex PCB, a hybrid board that blends the stability of traditional rigid boards with the flexibility of soft circuits. If you’ve ever picked up a smartwatch, unfolded a smartphone, or used a medical sensor patch, you’ve already held a rigid flex board in your hand.

Unlike a standard PCB, a rigid and flex PCB does exactly what it says on the label: part of it bends, and part of it doesn’t. That combo opens up a whole new world for engineers, especially when space is limited and movement is expected.

1. What Is a Rigid Flex PCB?

Let’s keep this simple.

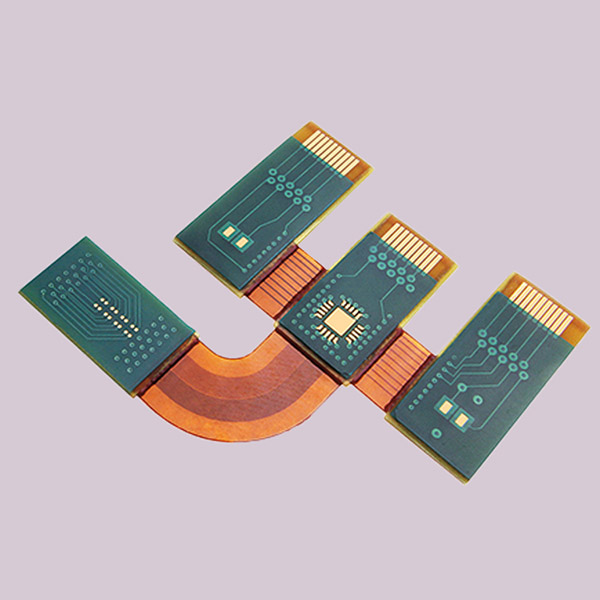

A rigid flex PCB is a circuit board that combines rigid sections (typically made from FR4) and flexible layers (often polyimide). These layers are laminated into a single structure, so there are no connectors between them, no soldered jumpers, no cabling.

It acts like one board, even though parts of it fold.

This makes rigid flex rigid PCBs perfect for 3D designs. Need to wrap a circuit around a hinge? Done. Need a board that folds during installation but stays rigid once placed? That’s what flexible rigid PCBs are built for.

In a PCB rigid flex design, the flex portions connect the rigid sections internally. These flexible sections often experience bending, folding, and even constant movement. That’s why the material and stack-up matter so much.

If you’ve heard terms like “rigid flex printed circuit boards” or “flex-rigid PCBs,” they all mean the same thing: a board built to bend where it needs to, and hold firm everywhere else.

2. How Rigid Flex Circuit Boards Are Built

So how are these boards made? Spoiler: it’s not easy.

Building a rigid flex PCB requires more than just gluing a flex cable between two rigid boards. This is a full manufacturing process that blends multiple substrates into one precisely layered structure.

Here’s what goes into it:

1) Material Selection

It starts with choosing the right core materials. FR4 (a standard rigid material) forms the solid sections, while polyimide handles the flex regions. The two must bond well, and handle heat, stress, and movement.

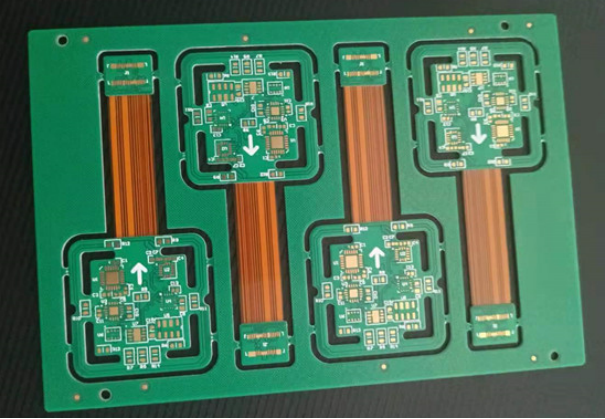

2) Layer Stack-up

The stack-up defines the layout: which layers are rigid, which are flex, and how they transition. This is where rigid flex PCB fabrication gets tricky, mistakes here lead to peeling, cracking, or delamination during use.

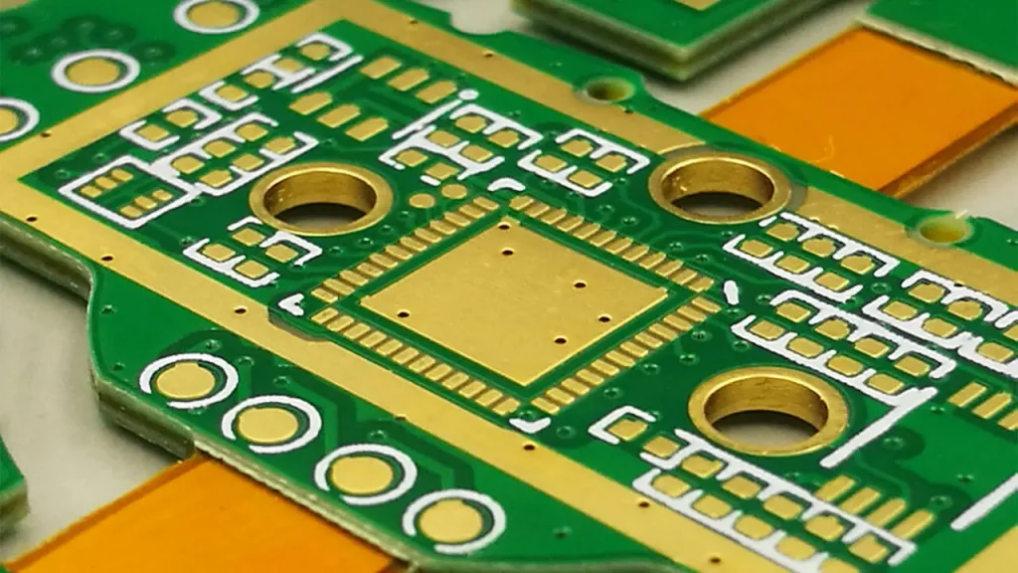

3) Drilling, Plating & Imaging

Both rigid and flexible zones are drilled for vias, then plated and etched. Because of the mix of materials, imaging and registration demand much tighter tolerances than in standard PCB production.

4) Bonding and Lamination

This step merges the rigid and flexible layers into one unified board. Done wrong? You’ll get bubbles, wrinkles, or broken traces. This is why only experienced rigid flex PCB suppliers should touch this kind of job.

5) Stiffeners and Reinforcements

Where needed, stiffeners may be added to strengthen connectors or mounting points, especially in a pcb flex rigid layout used in consumer devices or military gear.

3. Why Choose a Rigid Flex PCB Over a Traditional One?

So why not just use a standard rigid board with a flex cable? Or even two boards connected by a ribbon?

Because in most modern designs, that’s no longer good enough.

A rigid flex PCB replaces those connectors with permanent internal layers. That means:

- No cables to fail

- No bulky connectors

- No extra solder joints to crack

It’s all in one structure.

That’s what makes a pcb flex rigid layout not only sleeker, but also more durable. You’ll see this in aerospace tech, foldable phones, medical tools, even high-end audio gear. The electrical signals travel cleaner, and the whole device becomes more robust.

A rigid flex circuit board can also bend to fit weird enclosures. Traditional PCBs? Not a chance. And if your product has moving parts, hinge folds, or tight housing, only a flexible rigid PCB will survive without issues long term.

In short, the rigid and flex PCB combo solves a lot of problems:

- It saves space

- It increases durability

- And it keeps your design cleaner, simpler, and lighter

4. Real-World Applications of Rigid Flex Circuit Boards

Here’s where rigid flex boards show up in the wild, and why they’re now a staple in high-stakes industries.

1) Aerospace

Satellites, drones, and avionics rely on rigid flex PCBs to handle shock, vibration, and space constraints. You don’t want connectors shaking loose mid-flight.

2) Medical Devices

From pacemakers to surgical imaging tools, rigid flex printed circuit boards allow compact, reliable electronics that can fold into tight implantable or handheld designs.

3) Foldable & Wearable Electronics

Flexible displays, smartwatches, and fitness trackers depend on flexible rigid PCBs to allow movement while maintaining function.

4) Military and Defense

Rigid and flex PCBs are essential in field gear where ruggedness and lightweight construction are critical, radios, scopes, GPS units, targeting systems.

5) Industrial Controls & Robotics

Anywhere there’s motion and complexity, robotic arms, automated machines, sensor-packed panels, you’ll likely find a pcb rigid flex design managing the signals.

5. Rigid Flex PCB Benefits vs. Limitations

Let’s break it down.

5.1 Key Advantages

1) Space-saving and Compact:

Thanks to built-in flex layers, a rigid flex PCB takes up less room, fits in odd shapes, and replaces clunky wire harnesses.

2) Fewer Connectors = Fewer Points of Failure:

Every soldered joint or cable adds risk. With rigid flex circuit boards, everything’s integrated, so fewer things go wrong.

3) High Reliability:

Used in life-critical and mission-critical systems, rigid flex PCBs offer long-term durability even in harsh, high-vibration environments.

4) Excellent Signal Integrity:

Shorter paths between layers, fewer interconnects, and tightly controlled impedance mean cleaner, faster data transmission.

5.2 Limitations to Consider

1) Higher Rigid Flex PCB Cost:

The benefits don’t come cheap. More layers, custom tooling, and tight tolerances mean rigid flex PCB fabrication costs more upfront.

2) Longer Lead Times:

Because of the complexity, especially with quick turn rigid flex PCB jobs, production can take longer than standard PCBs.

3) Complex Design Rules:

You need to account for bending zones, strain relief, and mechanical movement. Mistakes in your pcb flex rigid layout can cost you more than just time, they can kill your product’s performance.

6. Rigid-Flex PCB Cost: What Drives the Price?

There’s no getting around it, rigid flex PCB cost is higher than traditional PCBs. But once you understand what you’re paying for, the price starts to make sense.

Here’s a breakdown of the key pricing factors:

| Cost Factor | Why It Matters |

| Layer Count & Stack-Up | More layers = more material, more lamination steps, and more time. While a basic pcb rigid flex might have 4–6 layers, complex designs can exceed 10. |

| Bend Areas & Transitions | Any area that flexes adds complexity. Flexible rigid PCB zones require extra reinforcement, testing, and precision to prevent stress failure. |

| Material & Surface Finish | High-grade materials like polyimide, ENIG finish, and low-loss copper drive up cost. These are common in rigid flex PCB fabrication for high-reliability products. |

| Quick-Turn Production | Need it fast? A quick turn rigid flex PCB will cost more due to expedited sourcing, tighter deadlines, and additional QA cycles. |

| Tooling & Revisions | Rigid and flex PCB designs often need custom tooling. Even small layout changes may trigger new setup costs or full-stack redesigns. |

Pro Tip: Simplify early. If you’re building a prototype, reduce complexity up front and involve your rigid flex PCB supplier during layout. It’ll save money and time down the line.

7. How to Choose the Right Rigid Flex PCB Supplier

Not all PCB shops can handle rigid flex. And choosing the wrong one? That’s an expensive mistake waiting to happen.

Here’s what to look for in a trustworthy rigid flex PCB manufacturer or supplier:

1) Specialized Experience

Ask how many rigid flex circuit boards they’ve built, and for which industries. If they’ve only done simple 2-layer jobs, they may not be ready for your multilayer flexible rigid PCB.

2) Certifications Matter

Your supplier should have IPC, ISO 9001, and possibly medical or aerospace certifications depending on your end use. Quality control isn’t optional when you’re working with pcb flex rigid builds.

3) Prototyping Support

Rapid prototyping isn’t just about speed. You need feedback on your design, help with the rigid flex PCB fabrication stack-up, and guidance on material selection. The best suppliers do more than quote, they collaborate.

4) Real Engineering Input

A proper flex rigid PCB manufacturer will run DFM (Design for Manufacturability) checks and flag risks. If your stack-up isn’t balanced or your bend radius is too tight, you want to know before production starts.

5) Logistics & Testing

Good suppliers offer more than production, they’ll test continuity, impedance, and flex cycles. Some even offer quick turn services if you’re under deadline pressure.

Need a recommendation? Only work with a rigid flex PCB supplier that shows you actual builds, not just brochures.

8. Design Tips for First-Time Engineers

If you’re new to designing rigid flex circuit boards, here are some field-tested tips to help you avoid painful (and costly) mistakes.

1) Respect the Bend Radius

Too tight, and your pcb flex rigid area will crack. A general rule? Keep your bend radius at least 10x the thickness of the flex layer. More is better.

2) Avoid 90-Degree Trace Angles

On flexible rigid PCBs, sharp corners concentrate stress. Use curves or 45° angles to reduce the risk of delamination or cracking during bending.

3) Add Strain Relief

Use tear-drop vias, fillets, and stiffeners around mechanical stress points. These small design choices can massively improve board lifespan, especially in rigid flex rigid PCBs that fold repeatedly.

4) Control Impedance Across Transitions

Signals don’t care that your trace crosses from rigid to flex. But your performance will suffer if impedance isn’t matched across zones. Work closely with your rigid flex PCB manufacturer to model signal paths.

5) Final Check Before Handoff

Before you submit files to a rigid flex PCB supplier, verify:

- Your stack-up is symmetrical

- Your material choices are realistic

- You’ve labeled flex vs. rigid zones clearly

- You haven’t placed vias or pads in bend areas

9. The Future of Rigid-Flex PCB Technology

The demand for rigid flex PCBs is growing fast, and not just in traditional industries like aerospace or defense. As electronics become smaller, smarter, and more wearable, the future of rigid flex circuit boards is getting even more flexible.

Here’s where things are heading:

- Smart Fabrics & Wearables

Flexible rigid PCBs are being integrated into biometric shirts, AR headsets, and health-monitoring patches.

Their ability to bend, twist, and stretch without failure makes them ideal for wearable and body-mounted tech.

- Foldable Consumer Electronics

Foldable phones, tablets, and rollable screens rely on pcb flex rigid designs to withstand continuous motion.

Expect more brands to switch to rigid flex rigid PCBs for sleek, bendable, and robust internal layouts.

- Biocompatible & Implantable Devices

In the medical space, rigid and flex PCBs are making implants smarter and diagnostics more compact.

Rigid flex printed circuit boards are already appearing in pacemakers, surgical tools, and neuro devices.

- AI-Optimized Layouts

Artificial intelligence is assisting with layout, routing, and impedance modeling for complex rigid flex PCB fabrication.

Soon, AI could generate entire stack-ups and material selections, optimizing both cost and performance.

10. Rigid-Flex PCB FAQs

11. Summary

Let’s recap what makes a rigid flex PCB the go-to solution for today’s most advanced electronic products.

Unlike standard boards, rigid flex circuit boards combine stability and movement into a single design. They eliminate unnecessary connectors, reduce failure points, and open up space for tighter, lighter builds.

You’ll find rigid flex boards in wearables, drones, medical gear, satellites, and more, anywhere performance matters and space is limited.

They do cost more, and they take more time to design. But the benefits? Fewer issues in the field, better signal integrity, and devices that actually work in the real world.

When built right, by the right rigid flex PCB supplier, these boards outperform just about anything else.

If you’re designing your next project and need a compact, high-reliability board, it might be time to switch from rigid… to rigid flex.

Latest Blog

Contact Info

Phone: +86-755-82882936

Email: [email protected]

WhatsApp: +86-13570802455

Wechat: +86-13570802455

Address: 2nd floor,D Bldg.,Electric Link Technology Bldg.,Gongming,Guangming New Dist.,518106 Shenzhen, China