BOM vs DIP vs SMT vs SMD

Table of Conent

Table of Conent

BOM table

The Bill of Materials, or BOM (Bill of Material), is a document that describes the product structure in detail in the form of data. In the SMT processing process, BOM includes key information such as the name, quantity, and mounting position number of the material. It is the core reference material in the programming of the placement machine and the confirmation process of IPQC (In-Process Quality Control).

1. The BOM referred to usually, that is, the BOM in a narrow sense, mainly refers to our initial understanding of BOM, that is, the bill of materials, which is what we usually call product structure. This is a narrow interpretation of BOM.

2. The BOM in a broad sense is a comprehensive summary of the product structure and process flow of a certain material, combining materials and processes to form a BOM that conforms to actual production. Therefore, the broad BOM should be understood as a combination of product structure and process flow.

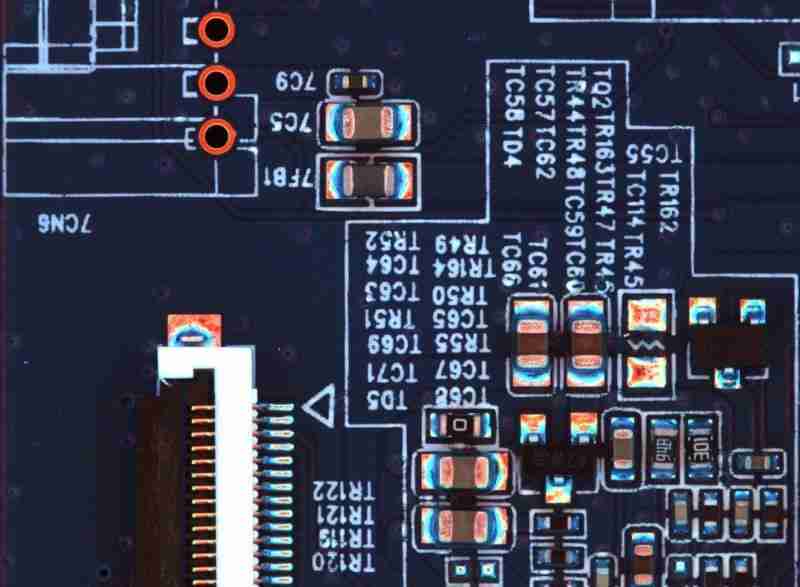

Picture of BOM table

DIP package (Dual In-line Package)

Also called dual in-line package technology, it refers to integrated circuit chips packaged in dual in-line form. Most small and medium-scale integrated circuits use this package form, and the number of pins generally does not exceed 100. The CPU chip in the DIP package has two rows of pins and needs to be inserted into a chip socket with a DIP structure.

SMT

Surface mount technology, also known as “Surface Mount Technology” or SMT for short, is a circuit assembly technology that solders surface mount components to specified locations on the surface of a printed circuit board. Specifically, the technology first applies solder paste to PCBs, and then precisely places the surface mount components on the pads coated with solder paste. By heating the printed circuit board, the solder paste melts, and after cooling, the connection between the element and the printed circuit board is completed.

This equipment is an SMT placement machine produced by assypcb; at the same time, it also includes Yamaha and Panasonic brand placement machines.

SMD

SMD surface mount devices (Surface Mounted Devices) are provided by Shenzhen SMT manufacturers In the initial stage of electronic circuit board production, through-hole assembly relied entirely on manual operation. With the introduction of the first automated machines, they could place some basic pin components. However, manual operation was still required for wave welding of complex components. About twenty years ago, the advent of surface mount components marked the beginning of a new era. From passive components to active components to integrated circuits, they eventually evolved into surface mount devices (SMD) and were able to be assembled by pick-and-place equipment. For a long time, it was generally believed that all pin components would eventually adopt SMD packaging.

Latest Blog

Contact Info

Phone: +86-755-82882936

Email: [email protected]

WhatsApp: +86-13570802455

Wechat: +86-13570802455

Address: 2nd floor,D Bldg.,Electric Link Technology Bldg.,Gongming,Guangming New Dist.,518106 Shenzhen, China