Surface Mount PCB: Evolution of Compact Electronics

Table of Conent

Table of Conent

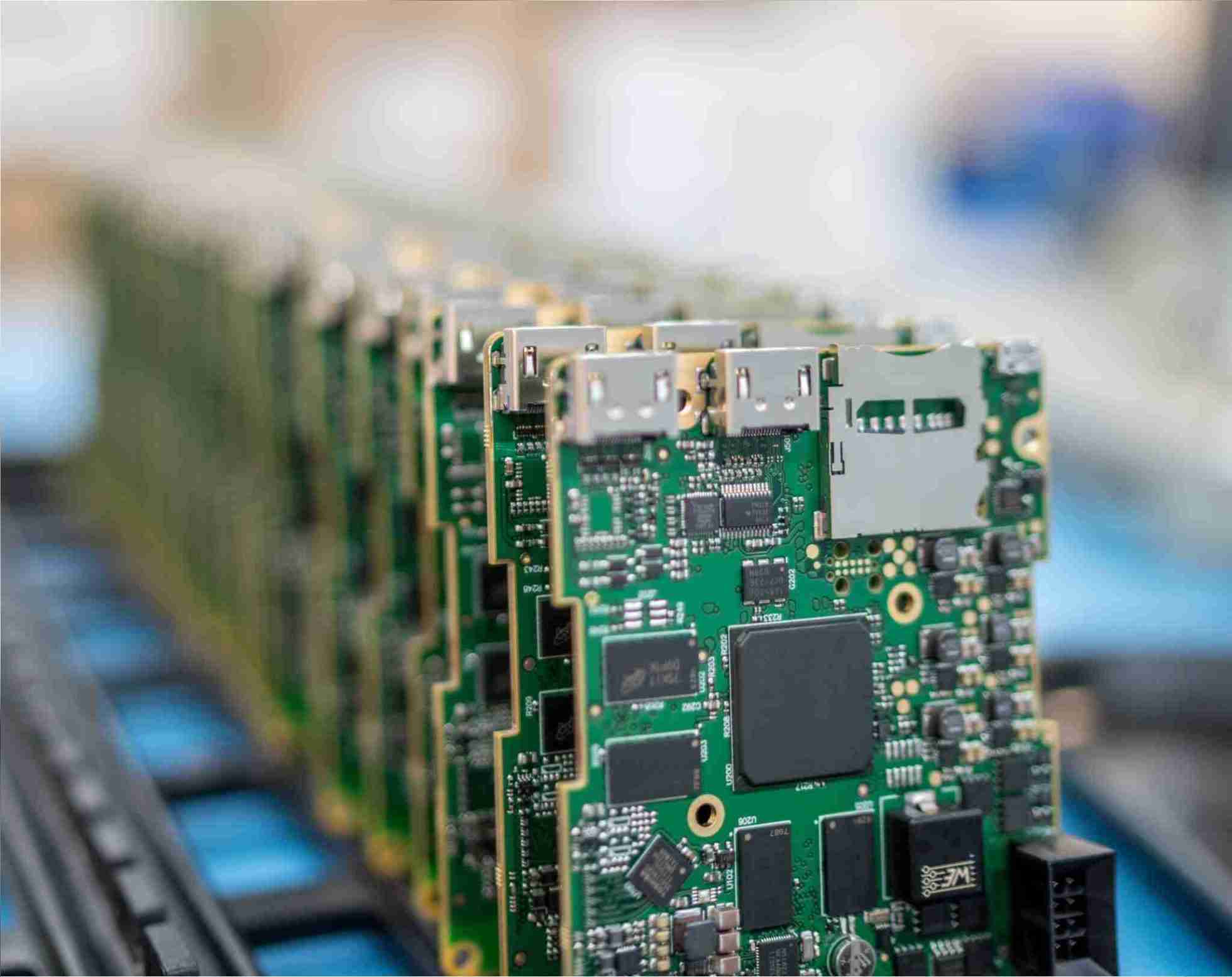

Surface Mount PCBs (Printed Circuit Boards) have revolutionized the design, manufacturing, and use of electronic devices. This compact, efficient solution has enabled the miniaturization of consumer and industrial products. From smart phones and laptops, to medical equipment and aerospace parts.

Surface Mount PCBs: What You Need to Know

SMT PCBs are characterized by their compact design, which makes efficient use of available space. SMT components are able to be placed closer together due to the lack of bulky through holes. This allows for a reduction in overall product size and weight. In turn, this allows for the creation of smaller electronic devices that are more portable and visually appealing.

Evolution of SMT PCB Technology

Surface mount technology dates back to the 1960s. The concept was introduced to meet the growing demand for smaller, more compact electronic components. SMT was not widely adopted until the 1980s, largely due to the explosive growth of the electronic industry and the demand for more efficient manufacturing methods.

Early Developments

SMT-PCB faced many challenges in its early years, including a limited supply of components that were suitable and difficulties achieving reliable connections.

The Rise of Automated Assembly

Automated surface mount assembly equipment (SMA) revolutionized manufacturing as technology improved. Pick-and-place machines are specialized machines that can precisely place and solder SMT parts onto PCBs. They improve production speed and accuracy when compared with manual assembly.

SMT PCBs are being adopted by a variety of industries due to the advent of SMA equipment and the refinement of SMT components.

Advanced Materials and Processes

SMT PCBs have seen significant improvements in materials and manufacturing processes. SMT PCBs have improved in reliability, performance and cost effectiveness due to innovations in solder alloys and surface finishes.

In response to environmental concerns about lead, new soldering alloys and component designs have been developed to ensure reliable connections. The use of advanced substrates such as flexible circuits and high-frequency laminates has also expanded the application of SMT PCBs in specialized fields like telecommunications.

Benefits of SMT PCB

SMT PCBs are becoming more popular due to their many benefits. They can be used for a variety of electronic applications.

Cost Efficiency

SMT PCBs are more cost-effective than traditional through-hole methods due to the automated assembly and manufacturing process. The mass production of SMT parts and the improved efficiency of assembly lines has driven down manufacturing costs. SMT PCBs are now more affordable for many applications.

Improved Reliability

The reliability of SMT PCBs has also been improved compared to through-hole counterparts. Solder joints between SMT components on the PCB and SMT components are more robust, less susceptible to mechanical stresses, vibrations, and thermal cycling. This results in a product with a longer life span.

Enhanced Flexible

SMT PCBs are versatile beyond their compactness and performance. SMT’s increased flexibility and ability to place components both on the front and back of the board has allowed engineers to design more complex circuits.

Applications for SMT PCB

SMT PCBs are a versatile technology that is used in a variety of industries, including consumer electronics, industrial equipment and medical devices.

Consumer Electronics

Consumer electronics is the most common application of SMT PCBs. The demand for smaller, portable and feature-richer devices is always increasing. SMT PCBs are used in smartphones, tablets, laptops and other personal electronics to create compact and efficient designs.

Industrial and Automotive Electronics

SMT PCBs are used in industrial and automotive applications as well, where reliability, compactness, and high performance electronics are essential. The advantages of SMT-PCBs make them an essential component for a wide range of industries, from industrial control systems to automotive electronics.

Medical and Aerospace Electronics

Medical and aerospace industries have also adopted SMT PCBs, due to their strict requirements for reliability and precision. SMT PCBs are essential for ensuring safety, dependability and performance in these electronic systems. These systems range from medical imaging equipment and diagnostics to satellites and avionics.

Telecommunications and Networking

Telecommunications and networking have been among the first industries to adopt SMT PCBs, due to their need for compact, high-density and high-speed electronic components. From routers to switches, base stations, and satellite communication systems, SMT PCBs are an essential part of modern communication networks.

SMT PCB Technology Advancements

Surface Mount PCBs are constantly evolving to meet the demands of the modern electronic devices.

Miniaturization of Fine-Pitch Components

The continued miniaturization and development of fine-pitch PCB designs are two of the biggest advancements in SMT technology.

Micro-scale and Nano-scale components such as 0201 (0.25×0.125mm) and 01005 (0.40×0.2mm) have pushed the limits of SMT PCB Design, requiring specialized production techniques and equipment in order to ensure reliable assembly.

Multi-Layer and Flexible Designs

Multi-layer PCBs and flexible designs are another area where SMT technology has advanced. Multi-layer PCBs are able to create more complex circuits with the addition of copper layers, ground planes and advanced routing capabilities.

Flexible PCBs on the other had enabled the integration of electronic into non-planar or curved surfaces. This has expanded the design options for a variety of applications from wearable devices, to conformable electronics.

High-Frequency High-Speed Circuits

The SMT PCB has evolved to support circuits with high frequencies and speeds. SMT PCBs that can handle signals up to GHz range have been created using specialized materials such as high-frequency laminates and low-loss dielectrics.

These advances are especially important for applications such as telecommunications systems, radar systems and high-speed transmission of data, where reliable and efficient handling high-frequency signals are of the utmost significance.

Embedded Components and Integration

The concept of embedded components is gaining popularity to improve the functionality and integration of SMT PCBs. This method involves the direct integration of passive components such as resistors and capacitors into the PCB substrate. It reduces the board size and component count.

Embedded active components (also known as embedded die technology) are highly efficient and compact electronic systems that can be created by integrating active components such as integrated chips and power management modules within the PCB layers.

3D Printing and Additive Manufacturing

SMT PCBs are also being impacted by 3D printing and additive manufacturing technologies. Inkjet and aerosol-jet techniques allow the direct deposition on flexible or rigid substrates of conductive components and traces. This allows the creation of custom PCBs that are made to order without using traditional subtractive manufacturing methods.

This method offers greater design flexibility, faster prototypes, and the possibility of integrating novel materials and components. It further expands the possibilities of SMT-PCB technology.

Environmental Sustainability and Eco Friendly Practices

The SMT PCB Industry has been working on reducing the environmental impact of their manufacturing processes and products as the global focus continues to increase. The industry has developed more eco-friendly products, including laminates free of halogens and lead-free alloys.

These eco-friendly practices help to reduce the environmental impact of SMT PCBs and also align with the growing demand for greener electronic products.

Future Trends and Challenges

The success of SMT technology in PCB manufacturing is unquestionable. However, it continues to face challenges and evolve trends that will influence its future development.

Miniaturization of Complexity

In the relentless pursuit of smaller and more powerful electronic devices, with more features, there is a constant need for SMT PCBs to be further miniaturized. The increasing density of electronic components has led to the development of more complex component designs and finer pitch sizes.

Thermal Management & Power Dissipation

The challenge of managing heat and thermal management is becoming more important for SMT PCB designs as electronic devices get smaller and power dense. Thermal vias, heat sinks and specialized materials have been developed to address thermal issues.

Environmental Sustainability

In the SMT PCB Industry, the growing emphasis on environmental sustainability led to the adoption and exploration of eco-friendly manufacturing methods. The industry is also exploring ways to improve SMT PCB recyclability, and their end-of life management to minimize the environmental impact.

Advanced Assembly Techniques

Surface mount PCB production is improving due to the continuous improvements of automated surface mounted assembly equipment. These include faster pick-and-place machines, advanced vision systems and higher speed pick-and place machines.

Emerging Technologies

New materials and technologies are being developed as the electronics industry develops. These new materials and technologies may have an impact on the future of SMT design and manufacturing. The integration of printed and organic electronic components, 3D printed parts, and flexible electronics could introduce new challenges and opportunities for SMT PCB design.

Materials and Processes Advancements

The continued development of materials and manufacturing methods for SMT PCBs is a significant area that will continue to be developed in the future. The exploration of new materials such as thermoplastics with high performance and composite laminates as well as refinement of current materials to improve their electrical, mechanical, and thermal properties are all part of this.

Moreover, improvements in additive manufacturing, such as 3D printing or direct writing processes, could lead to PCB fabrication techniques that are more flexible and customizable, with a faster turnaround time and greater design flexibility.

Improved Integration and Functionality

The future of SMT technology is likely to focus on integration and functionality as the demand for smaller and more feature-rich devices continues. The future of SMT PCB technology will likely focus on increased functionality and integration.

It is crucial to develop next-generation wearables and IoT devices that can integrate more functionality into a smaller space.

Intelligent and Adaptive PCB Designs

These intelligent systems can be used to create PCB designs that are capable of adapting themselves to changes in requirements, environmental conditions and performance demands.

This could lead towards more efficient, resilient and autonomous electronic devices, with the capability to continuously monitor and optimise their performance.

Sustainability and Circularity

The future of SMT-PCB technology is likely to focus on eco-friendly design and circular approaches, as the industry continues its commitment to environmental sustainability.

The SMT PCB Industry can help create a circular economy by adopting these sustainable practices. This will reduce the environmental impact on electronic devices during their entire lifetime.

Conclusion

SMT PCBs have played an important role in the development of modern electronics, from consumer gadgets to medical equipment and industrial equipment.

SMT PCBs are poised to continue playing a vital role in the evolution of electronic systems and devices by embracing new technologies and addressing ongoing challenges.

Latest Blog

Contact Info

Phone: +86-755-82882936

Email: [email protected]

WhatsApp: +86-13570802455

Wechat: +86-13570802455

Address: 2nd floor,D Bldg.,Electric Link Technology Bldg.,Gongming,Guangming New Dist.,518106 Shenzhen, China