A Complete Guide to RF PCB and High Frequency PCB

Table of Conent

Table of Conent

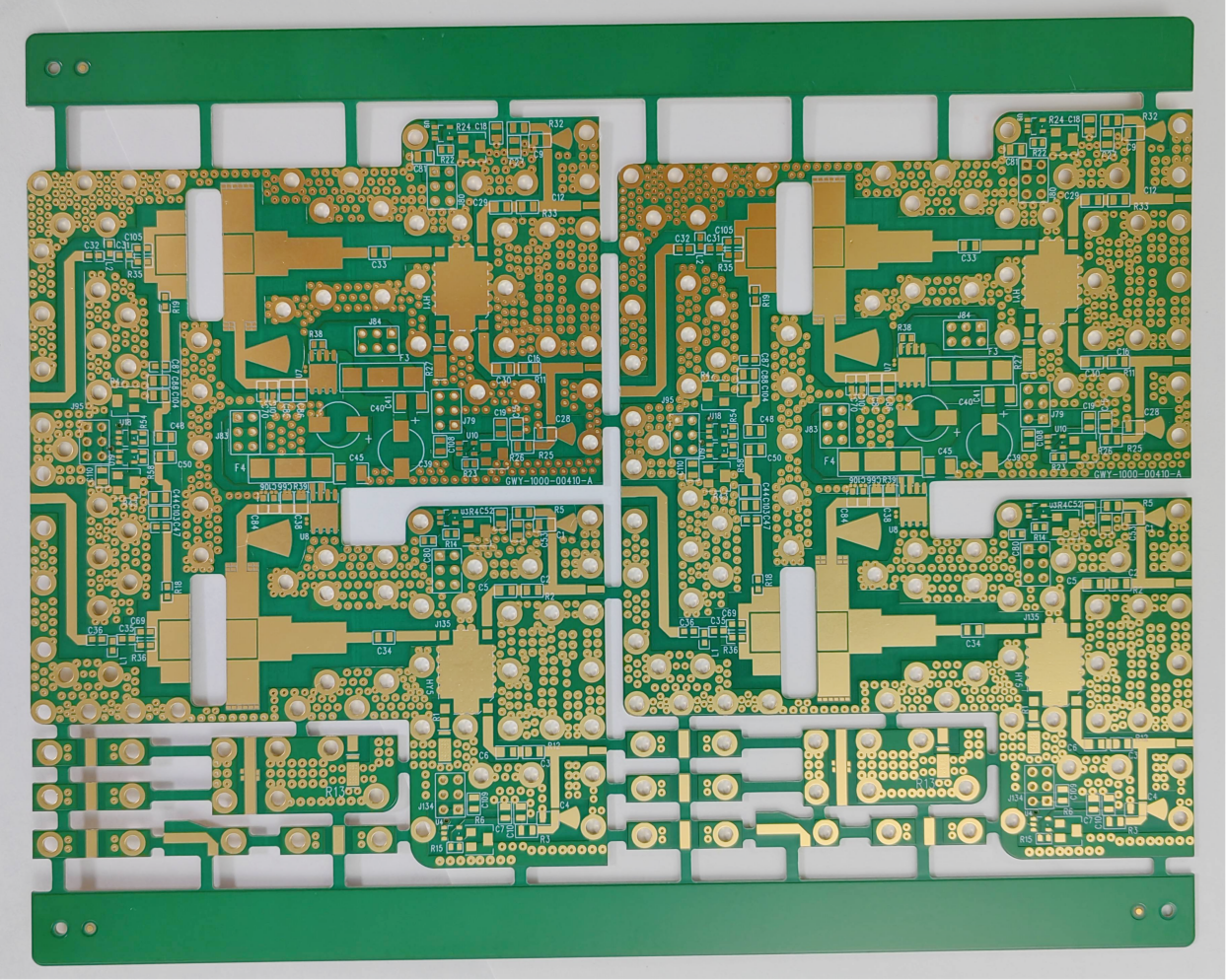

Let’s face it, today’s electronics aren’t just faster, they’re smarter, more compact, and way more demanding under the hood. And when you’re building anything that sends or receives a signal, be it a smartphone, radar system, or even a satellite, you can’t just slap down any old circuit board and hope for the best.That’s where the RF PCB and high frequency PCB manufacturers come in.

These aren’t your average boards. They’re built for speed, precision, and signal integrity. If a standard PCB is the family sedan, these boards are more like tuned sports cars, built for performance under very specific conditions. Whether you’re working in aerospace, military, telecom, or medical devices, ignoring these specialized circuit boards is a rookie mistake.

We’re going to break down everything you need to know: what sets an RF PCB apart, what makes a high frequency PCB manufacturer tick, and how to design and source the right one. From materials to manufacturers, we’ve got you covered.

1. What Is an RF PCB? (And Why It’s Not Just a Buzzword)

An RF PCB, or radio frequency printed circuit board, is exactly what it sounds like, it’s a circuit board specifically designed to carry signals in the radio frequency range. That typically means anything above 100 MHz and often into the gigahertz zone. In short, it’s the brain of anything wireless.

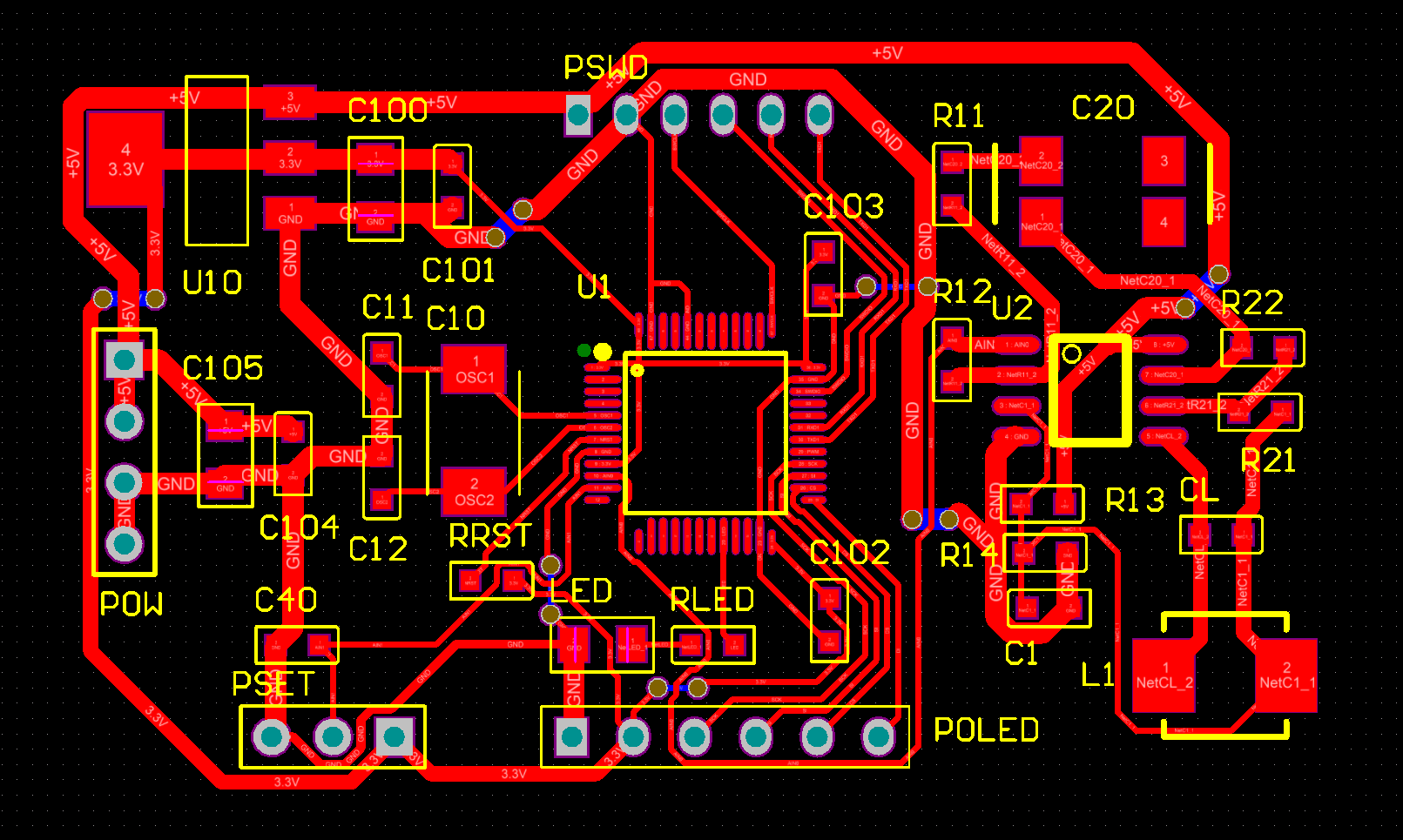

Now, let’s not confuse this with a regular PCB. An RF circuit board isn’t just about routing signals from A to B, it’s about doing it cleanly, with minimal interference, loss, or distortion. That’s why RF PCB design takes into account things like impedance matching, dielectric loss, and electromagnetic shielding in ways regular boards don’t even touch.

Picture a walkie-talkie, a GPS device, or a Wi-Fi router. All of those are powered by some form of RF board. And guess what? Not all RF PCBs are made equal. Some are multilayered, some are built with exotic materials like PTFE or ceramic-filled laminates, and others are just compact, single-layer RF prototype boards for quick testing.

You’ll often hear terms like RF printed circuit board or RF PCB board thrown around, these all refer to the same thing. But the real differentiator is in the material stack-up and layout, not just the label. And if your application relies on clean signal transmission? You need the right kind of RF PCB, no compromises.

2. The High Frequency PCB: Why Materials Make or Break It

So how’s a high frequency PCB different for high frequency PCB manufacturers?

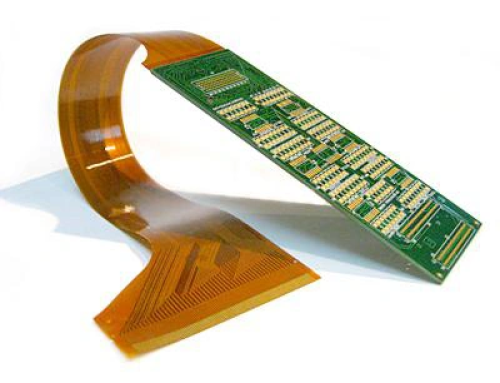

For starters, while all RF PCBs are designed for radio frequencies, not all high frequency PCBs are technically “RF.” A high frequency PCB manufacturer focuses on signal performance above 500 MHz, often going up to 10 GHz and beyond. But it’s the materials that really define the difference.

Regular FR4 won’t cut it here. You’re dealing with ultra-low loss materials like Rogers, Taconic, or Isola laminates. These high frequency PCB materials help maintain signal integrity over longer distances and higher frequencies. They’re also more thermally stable, which matters a lot when you’re working with power amplifiers or fast-switching circuits.

But the real challenge? These materials behave differently in the manufacturing process. They expand more. They’re softer. They can warp. And they cost more, too. So you don’t just need a good design, you need a manufacturer that knows how to handle this stuff.

When we say RF PCB material matters, we’re not just being picky. The wrong substrate can wreck your entire signal path. That’s why high frequency circuit boards are often custom builds. You can’t just grab any board off the shelf.

And here’s a tip: if your board is expected to function in a high-speed wireless device, it probably needs to be both an RF PCB and for a high frequency PCB manufacturer. The overlap is real.

3. Designing for Speed: RF PCB Design vs High Frequency PCB Design

If you think designing an RF PCB is just about choosing fancy materials and tracing a few lines, you’re in for a rude awakening. Both RF PCB design and high frequency PCB manufacturers’ designs require surgical precision. And while they share some DNA, there are some critical differences you need to know.

Let’s break it down.

3.1 RF PCB Design Essentials

Designing an RF circuit board means managing signal transmission at very high frequencies, often in the gigahertz range. That means you have to deal with things like:

- Controlled impedance: Your traces are basically tiny antennas.

- Minimal parasitics: Inductance and capacitance kill clean signals.

- Tight stack-ups: Even small material shifts affect performance.

- Precise trace geometry: Width, spacing, and layer count all matter.

Even a millimeter of trace routing error can lead to reflections, noise, or outright signal failure. So when it comes to RF PCB design, there’s no room for freelancing, it’s science, not art.

3.2 High Frequency PCB Design Differences

High frequency PCB manufacturer design takes the above and adds another layer of challenge. Here, you’re also looking at:

- Dielectric constant stability(Dk): It needs to be consistent across temperature and frequency.

- Low loss tangent: Essential to avoid signal attenuation.

- Thermal management: These boards heat up fast under high-speed operations.

The real trick is that high-speed designs demand both electrical performance and thermal reliability.

3.3 RF vs High Frequency Design: At a Glance

| Feature | RF PCB Design | High Frequency PCB Design |

| Frequency Range | ~100 MHz to GHz | 500 MHz to 10+ GHz |

| Key Focus | Impedance control, noise reduction | Signal integrity, thermal stability |

| Common Materials | PTFE, Ceramic, Polyimide | Rogers, Taconic, Isola |

| Common Use Cases | GPS, Bluetooth, Wi-Fi modules | Radar, RF amplifiers, high-speed comms |

| Stack-Up Complexity | Medium to High | High, especially in multilayer boards |

Whether you’re working on an RF circuit board design or a multilayer RF PCB design, planning is everything. One wrong move early on, and it’s game over for signal quality.

4. Shielding & Signal Integrity: Key RF Board Techniques

Let’s talk about what really makes or breaks your board once it’s powered up: signal integrity and shielding. When it comes to RF boards and high frequency PCBs, keeping those signals clean is priority number one.

4.1 Why Shielding Is Non-Negotiable

Without proper shielding, your RF PCB becomes a noisy, glitchy mess. Electromagnetic interference (EMI) can destroy signal clarity or, worse, affect nearby devices. A good RF shielding PCB:

- Prevents external signals from interfering with your circuit.

- Keeps your device from interfering with others.

- Helps reduce crosstalk between high-speed traces.

That’s why high-frequency devices often use copper enclosures, Faraday cages, or conductive coatings, even on multilayer boards.

4.2 Signal Integrity Must-Haves

Here’s a shortlist of things you should absolutely be doing for signal integrity in both RF PCBs and high frequency PCBs:

- Keep trace lengths short and matched

- Use ground planes for consistent return paths

- Avoid 90-degree trace angles

- Space sensitive signals away from noisy power lines

- Simulate everything before you send the design to the manufacturer

If your signals aren’t clean, you’ll get packet loss, reflection, jitter, or worse, your board won’t function at all.

Even if you’ve done your RF PCB or Microwave PCB design right, failing at signal integrity will wreck it. It’s like tuning a race car engine and forgetting to check the brakes.

5. Choosing the Right RF PCB Manufacturer

Designing a board is one thing. Getting it made right? That’s a whole different beast.

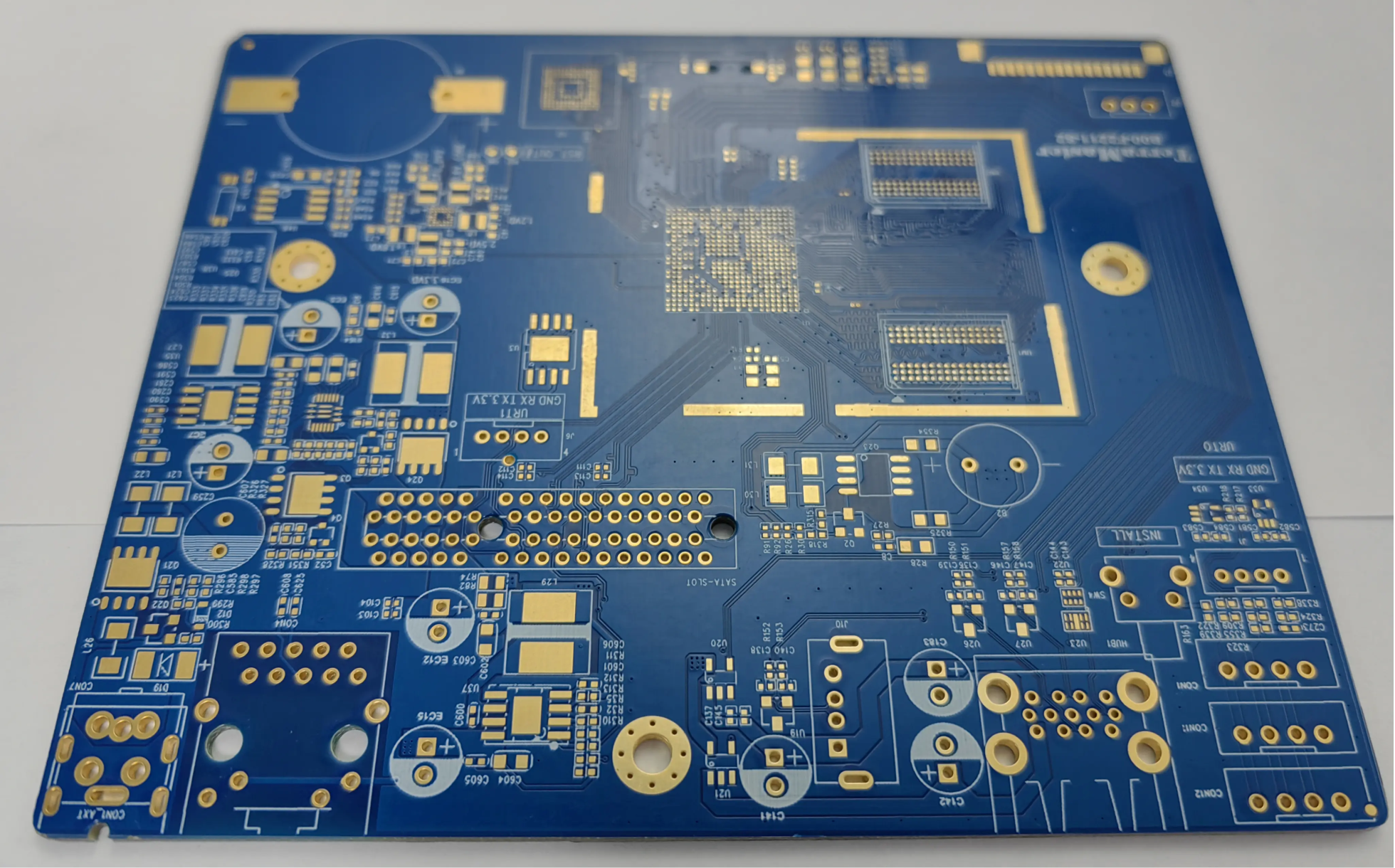

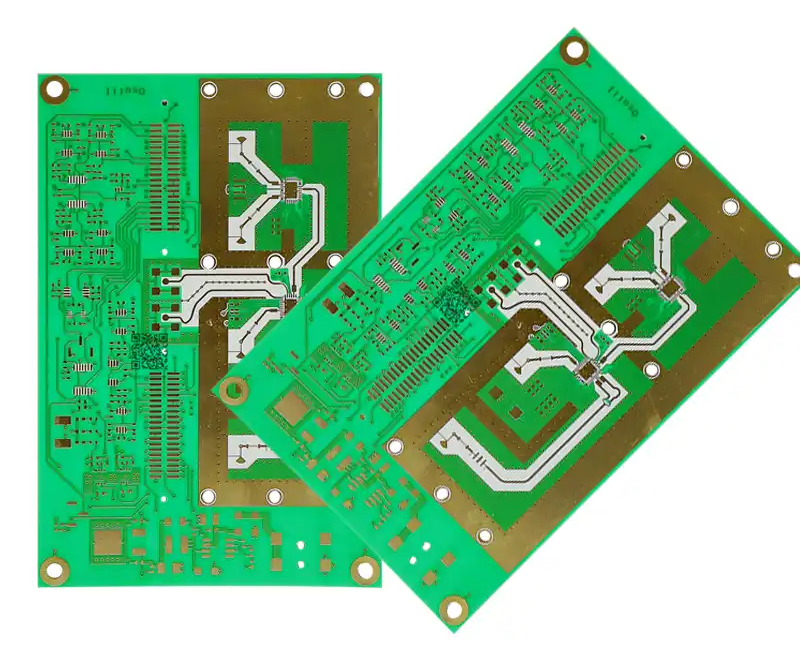

Whether you’re working on a complex high frequency PCB or a single-layer RF prototype board, your RF PCB manufacturer can make or break your project. No exaggeration, cheap shortcuts or lack of expertise will absolutely show in your final product.

5.1 What to Look For in an RF PCB Manufacturer

Before you send out that Gerber file, ask yourself:

- Do they specialize in high frequency PCB manufacturing?

- Can they handle exotic materials like PTFE or ceramic-filled laminates?

- Do they offer testing and validation options beyond the bare minimum?

- Can they produce multilayer RF PCB designs with tight tolerances?

It’s not just about what they claim, they need to show proof. That’s where datasheets, test reports, and real client samples come in.

5.2 Beware the “Yes-Man” Manufacturer

If a supplier says yes to everything and asks zero questions? Walk away.

A real RF PCB manufacturer or Microwave PCB manufacturer will push back if your layout has flaws, or if your material choice won’t hold up at 8 GHz. Silence isn’t professionalism, it’s a red flag.

5.3 Comparing Manufacturers: The Smart Way

Here’s a quick table to help separate the pros from the placeholders:

| Criteria | What to Expect from a Good Manufacturer | What to Avoid |

| Communication | Responsive, detailed, technical | Generic replies, no engineering feedback |

| Material Handling | Familiarity with high frequency PCB manufacturer materials | “We’ll try” answers or no material options |

| Testing | Flying probe, impedance, thermal testing | Just “visual inspection” |

| Prototyping Options | Offers RF prototype board builds | Full production only, no flexibility |

| Track Record | Past work in telecom, radar, or medical PCBs | Can’t share previous projects or yields |

A good RF PCB manufacturer will walk you through their process. They’ll show what they check during fabrication, how they deal with layer misalignment, and how they catch defects before shipping.

5.4 Pro Tip: Manufacturer vs. Assembly House

Don’t confuse an RF PCB manufacturer with an assembler. Some shops just solder your components onto boards they didn’t even fabricate. For high frequency PCB manufacturer builds, that’s risky business. Always ask:

“Do you fabricate the board yourself?”

If not, make sure you know exactly who does, and whether they’re qualified to handle complex designs and exotic materials.

5.5 Recommended: Y&T Technology Development Co.,Ltd.

If you’re looking for a reliable, cost-effective option that specializes in both RF PCB and high frequency PCB manufacturers, check out ASSYPCB.com.

With over 14 years of experience in PCB manufacturing and assembly, they’re a one-stop shop trusted by engineers across the US and Europe. From RF prototype boards to full-scale multilayer RF PCB design, they deliver the kind of performance and communication you’d expect from a top-tier supplier.

6. Testing & Prototyping Your RF PCB Assembly

Even with the best RF PCB design and materials, if your board isn’t tested properly, it’s a gamble. And in high-frequency applications, a failed board isn’t just inconvenient, it’s a project killer.

6.1 Testing Methods You Should Expect

Every legit RF PCB manufacturer should offer more than just a visual check. Here’s what to ask for:

- Flying probe testing: Great for low-volume or prototype runs.

- Impedance control verification: Ensures your signal traces match spec.

- X-ray inspection: Critical for BGAs and hidden joints.

- Thermal cycling: Stress-tests how the board handles temperature swings.

Don’t assume any of this is automatic. If your RF prototype board arrives untested, it’s practically unfinished.

6.2 Why Prototyping Matters (A Lot)

Prototyping isn’t optional. Before you order a big run of high frequency PCBs, you need to:

- Validate the stack-up and materials

- Confirm signal behavior in real-world conditions

- Identify layout or fabrication flaws early

Working with a partner likeY&T Technology Development Co.,Ltd. makes this easier, they handle RF PCB prototyping with the same care they put into large orders, including all the necessary QA checks.

7. Application Spotlight: Where These PCBs Shine

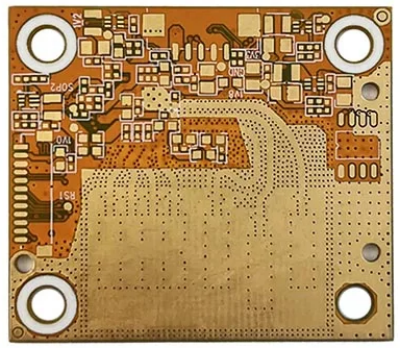

So where do RF PCBs and high frequency PCB manufacturers actually get used? Pretty much anywhere speed, precision, and reliability matter. Here’s a quick rundown:

Real-World Use Cases

- Telecom: Base stations, antennas, and RF switches

- Automotive: Advanced driver-assistance systems (ADAS), radar sensors

- Medical: Wireless patient monitors, MRI machines

- Aerospace: GPS, satellite communication, navigation

- Military/Defense: Secure comms, radar, jamming devices

And that’s just scratching the surface. As devices get smaller and more capable, the demand for high frequency circuit boards will only keep growing.

8. RF PCB and High Frequency PCB FAQs

9. Summary

To recap, RF PCBs and even high frequency PCB manufacturers aren’t luxuries, they’re necessities in modern electronics. From the materials you choose to the RF PCB manufacturer you work with, every detail matters.

Here’s the quick checklist:

- Understand your design goals before selecting materials.

- Use simulation tools to optimize signal integrity.

- Vet your manufacturer, not just for price but for testing, communication, and real-world experience.

- Prototype everything, don’t assume you got it right the first time.

If you’re serious about performance, the days of cutting corners are long gone. Trust your design, trust your testing, and trust a factory like Y&T Technology Development Co.,Ltd. to get the job done right.

Latest Blog

Contact Info

Phone: +86-755-82882936

Email: [email protected]

WhatsApp: +86-13570802455

Wechat: +86-13570802455

Address: 2nd floor,D Bldg.,Electric Link Technology Bldg.,Gongming,Guangming New Dist.,518106 Shenzhen, China