How Do You Choose Chip Inductors When Processing SMT Chips

Table of Conent

Table of Conent

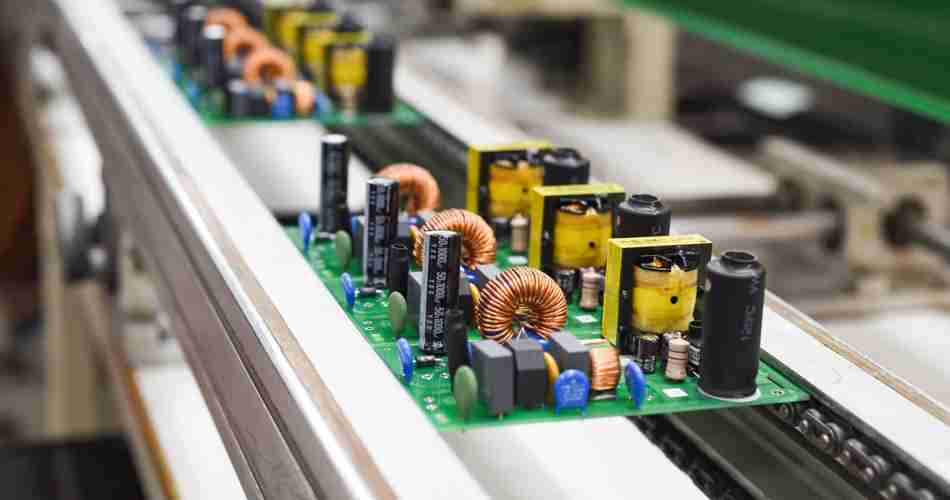

Today we will certainly talk about chip inductors. In SMT chip processing, chip inductors generally play the duty of choke, decoupling, filtering, and adjusting. There are 2 primary sorts of chip inductors: winding type and stacked type. So how do you select an ideal chip inductor when refining SMT chips? Here are some principles for choosing chip inductors.

1. The size of the chip inductor must be smaller sized than the width of the inductor to prevent extreme solder from producing extreme tensile stress during cooling and changing the inductance worth.

2. The accuracy of most chip inductors readily available on the market is ± 10%. If the precision is needed to be greater than ± 5%, it is needed to put an order in advance.

3. Some chip inductors can be soldered by reflow soldering and wave soldering, but some chip inductors can not be soldered by wave soldering.

4. When repairing, you can not replace the chip inductor based exclusively on the inductance. You additionally need to recognize the functioning frequency band of the chip inductor to guarantee its functioning efficiency.

5. The shape and size of chip inductors are similar, and there are no evident indicators of the shape. When manually soldering or patching, do not make the wrong placement or take the wrong components.

6. There are three common chip inductors at present: the very first is high-frequency inductors for microwaves. Suitable for usage in frequency bands above 1GHz. The second is high-frequency chip inductors. Suitable for powerful circuits and frequency option circuits. The third is global inductors. Generally suitable for circuits of 10s of megahertz.

7. Various products have different coil sizes. The very same inductance has different DC resistances. In high-frequency circuits, DC resistance has a great influence on Q value, so it should be focused on during style.

8. The optimum current allowed to pass is additionally a sign of chip inductors. When the circuit needs to birth a big current, this indication of capacitance have to be thought about.

9. When power inductors are utilized in DC/DC converters, the dimension of their inductance straight influences the working state of the circuit. In practice, the inductance can typically be changed by increasing or reducing the coil to obtain the best effect.

10. Wire-wound inductors are typically used in interaction devices operating in the 150 ~ 900MHz frequency band. In frequency circuits over 1GHz, microwave high-frequency inductors have to be used.

The above are the top ten factors to consider when selecting chip inductors in SMT chip handling. Only by better-selecting chip inductors can the high quality of SMT chip handling be far better ensured.

Latest Blog

Contact Info

Phone: +86-755-82882936

Email: [email protected]

WhatsApp: +86-13570802455

Wechat: +86-13570802455

Address: 2nd floor,D Bldg.,Electric Link Technology Bldg.,Gongming,Guangming New Dist.,518106 Shenzhen, China