BLOG LIST

the latest news & resources

Copper black pcb is also known as copper-based, black solder mask PCB. It is a circuit made from special black ink solder masks on a traditional pcb. The black solder mask is more shading-friendly than

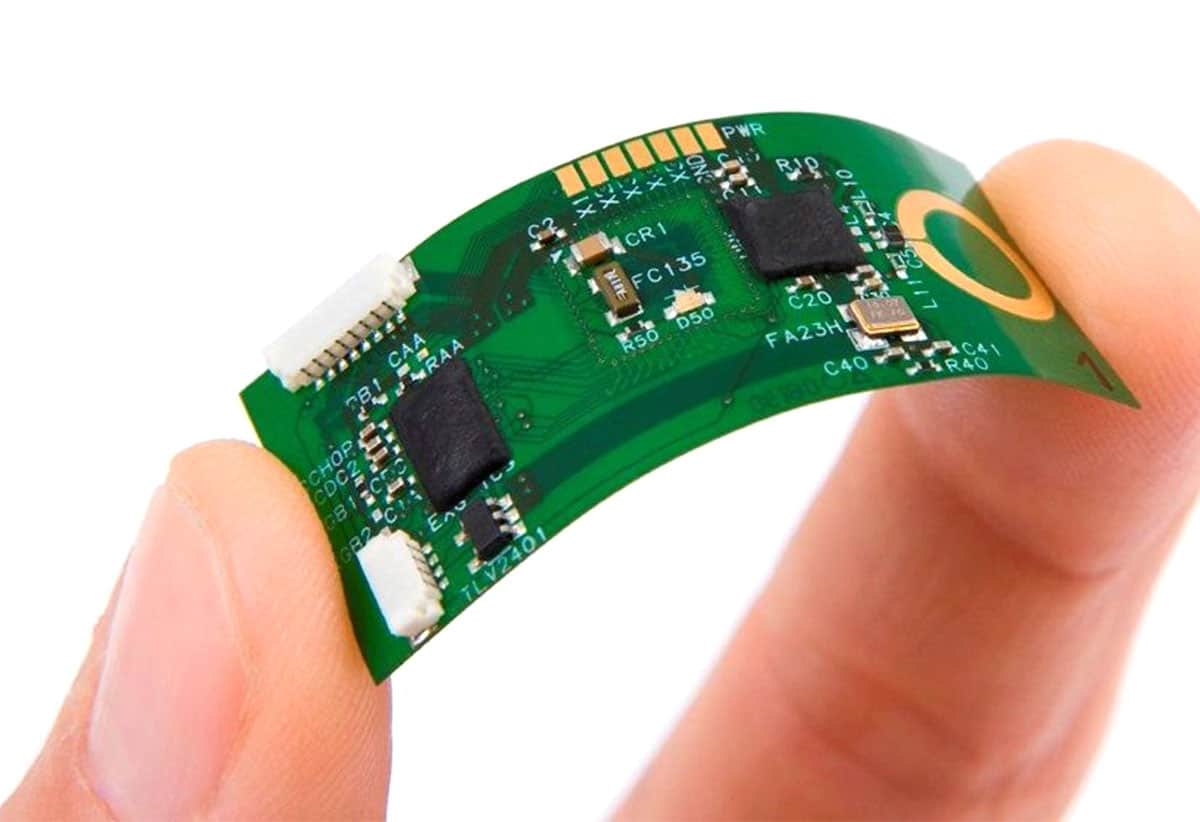

The conventional design and format of printed circuit boards(PCBs), as the demand for smaller and more productive electronic gadgets continues to grow, are being stretched to the limit. The increasing weight of electronic devices

FFSD connectors are high performance, high reliability printed circuit board connectors that are used to connect flat flexible cables (FFC/FPC), to flexible printed circuits. FFC/FPC connectors can adapt to different shapes and sizes and are

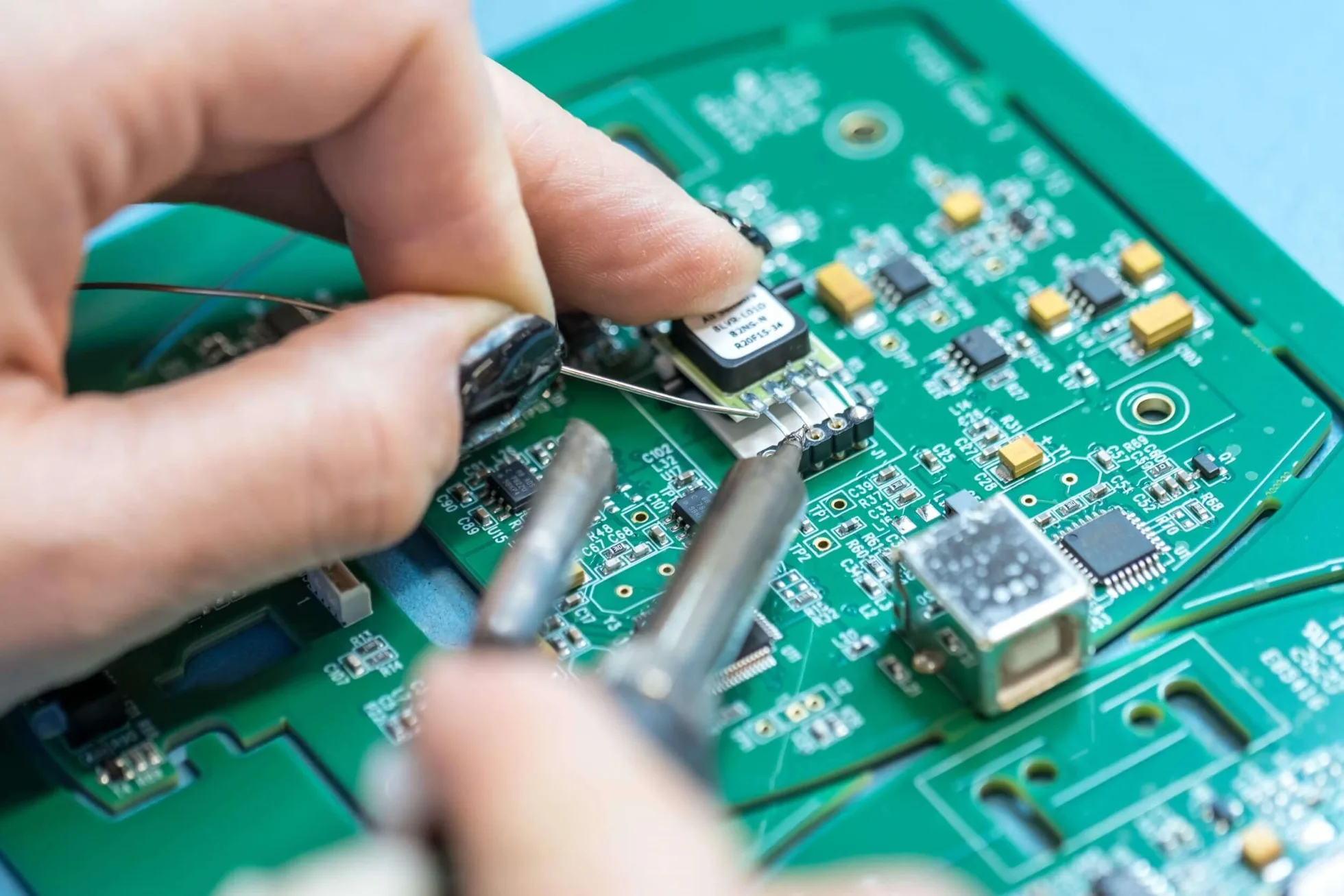

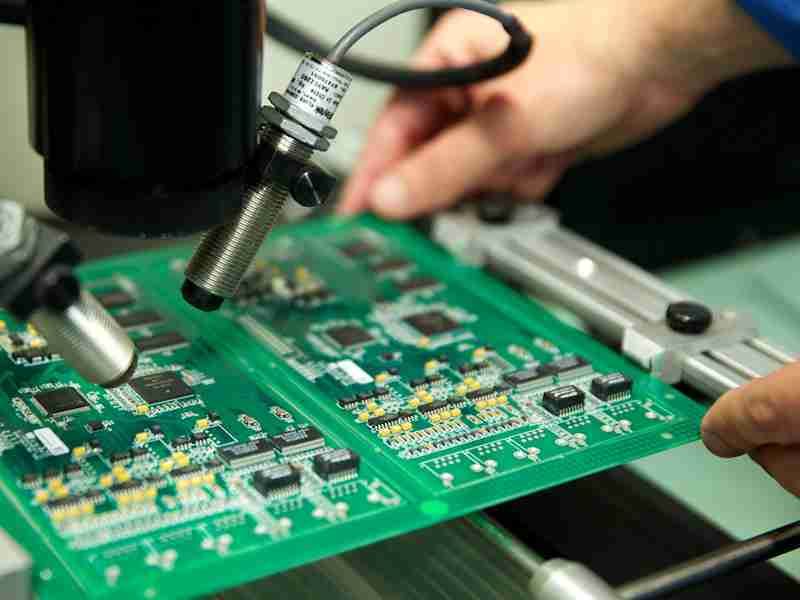

Printed Circuit Board Assembly is a fundamental viewpoint in advanced gadgets production, where components can be assembled onto a PCB for the purpose of making useful electronic gadgets.In the last few decades, PCB complexity has

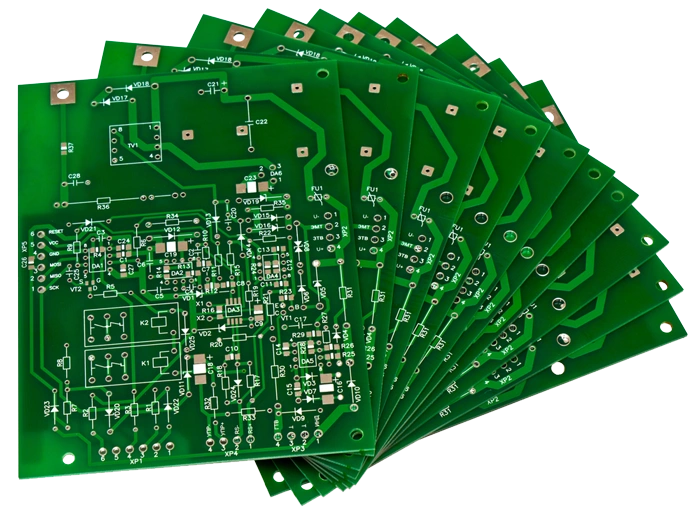

Printed Circuit Boards are the backbone of modern gadgets. They provide mechanical support and connect electronic components via conductive paths. PCB sheets are made with precision, advanced equipment, and specialized knowledge. This article will delve

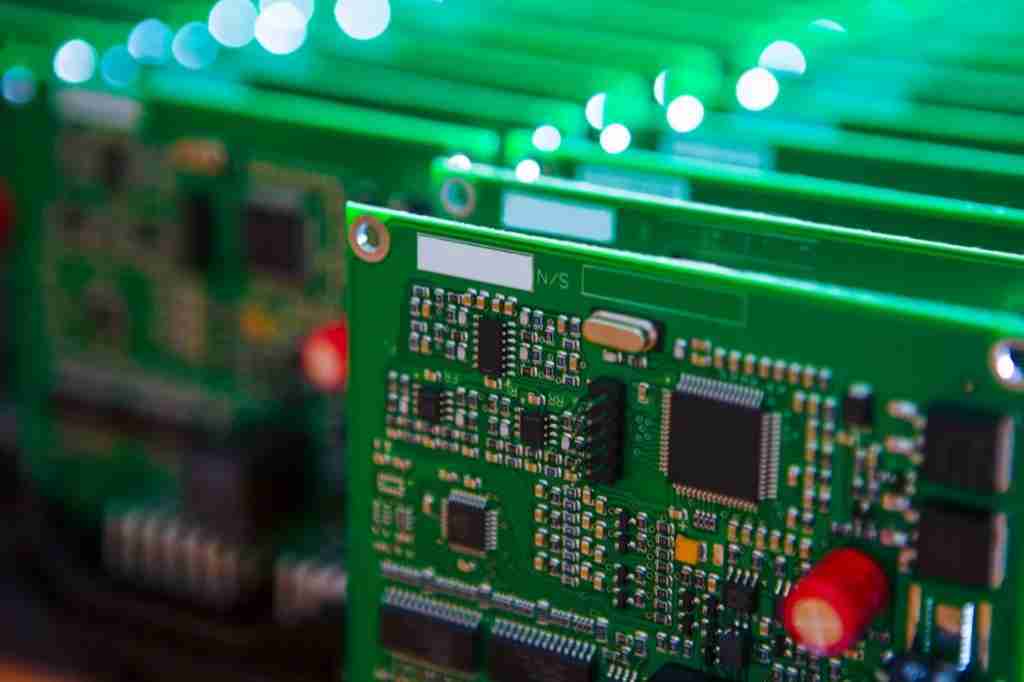

Printed circuit boards, or PCBs, are integral elements in nearly every electronic device used in the modern, rapidly changing world of electronics. These sheets act as the foundational system for electronic circuits, empowering the physical

In today's digitally driven world, electronic devices play an integral role in our daily lives. Whether it's the Smartphone in your hand, the computer on your desk, or the car you drive, most of these

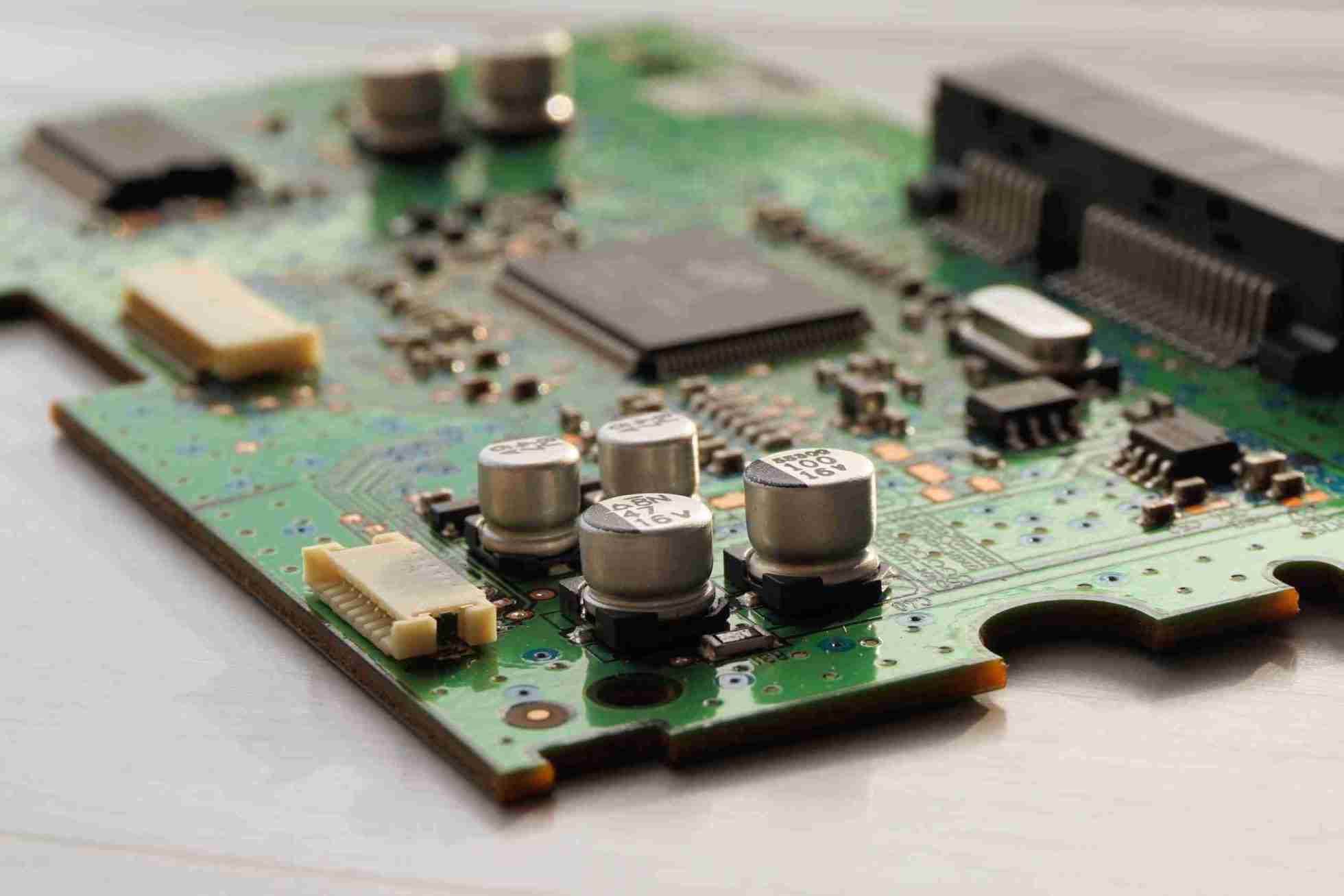

Printed Circuit Boards are the backbone of modern electronic devices. They are used to mount components such as resistors and capacitors. PCBs have evolved over time and different forms and instruments that ensure their efficient

Electronic fabrication is a vital area that includes the circuit card assembly (CCA) as well as printed circuit board (PCB). These types fall under the umbrella of electrical construction and fabrication building, with a

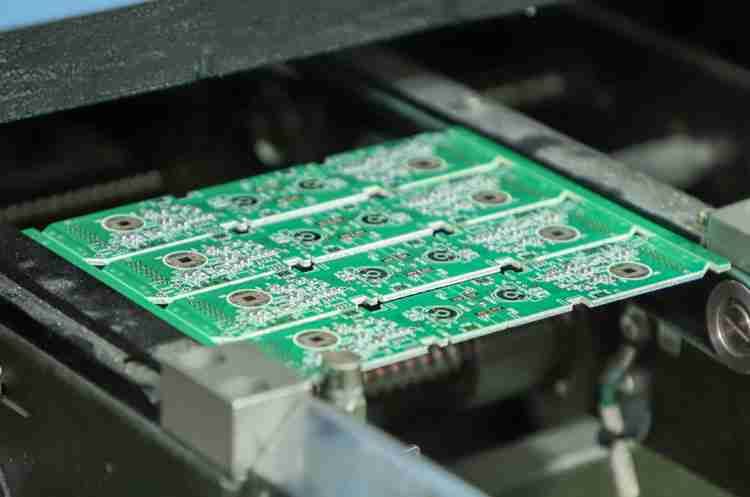

This article examines three key areas of PCB technology today: Proto PCBs and PCB boards fabrication. Their unique characteristics, their applications and the impact they have on businesses are explored. Flexible Circuit Boards: A new