BLOG LIST

the latest news & resources

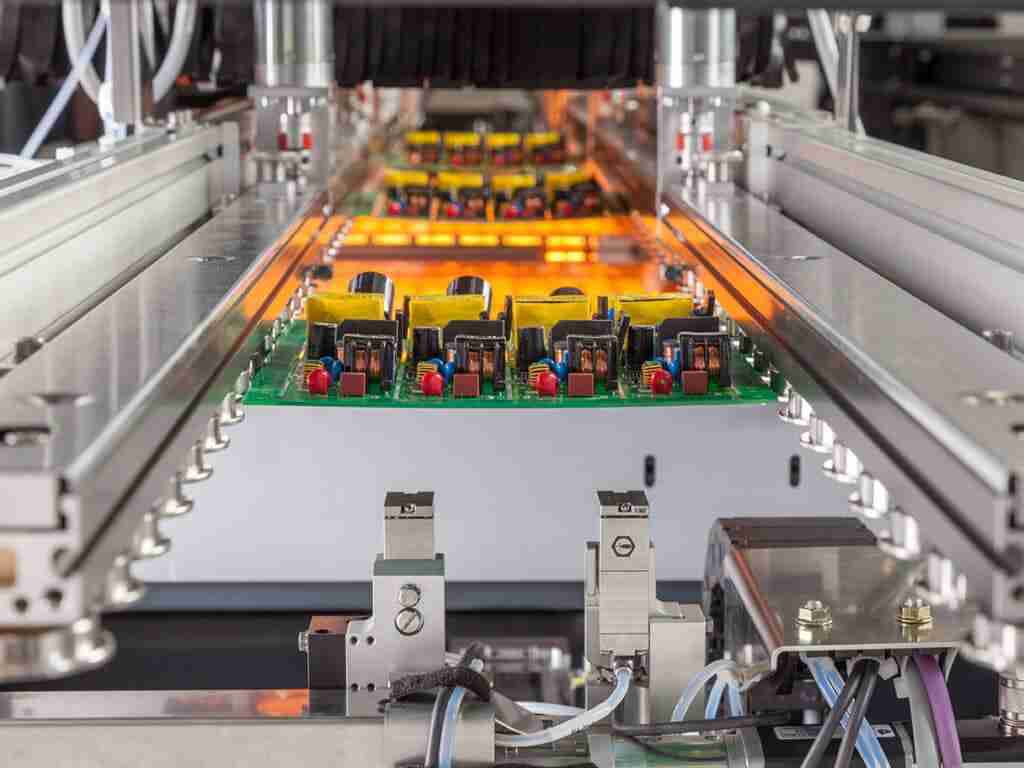

PCBA experts know the main benefits of automating the SMT device assembly process: reduced errors, increased yields, and consistent quality, but is automation always better? The use of SMT production line machines has become

Manual Welding In many aspects, manual welding has become almost an obsolete technique as more precise and reliable processes have been created. While hand welding was once a great technique, it has gradually declined

Abstract The structure of semiconductor materials has changed and become complex over time, so packaging also needs to evolve. To complement and handle the complexity of semiconductors, new integrated circuit SMT and through-hole DIP

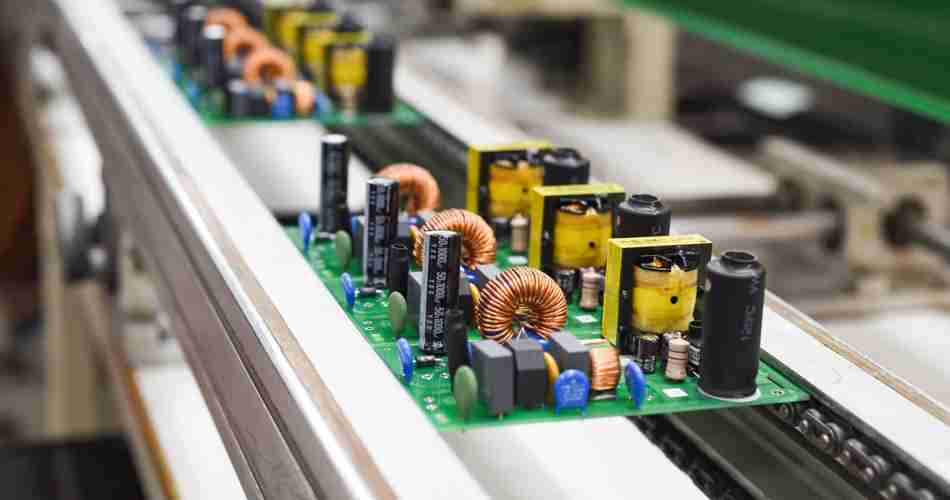

Today we will certainly talk about chip inductors. In SMT chip processing, chip inductors generally play the duty of choke, decoupling, filtering, and adjusting. There are 2 primary sorts of chip inductors: winding type

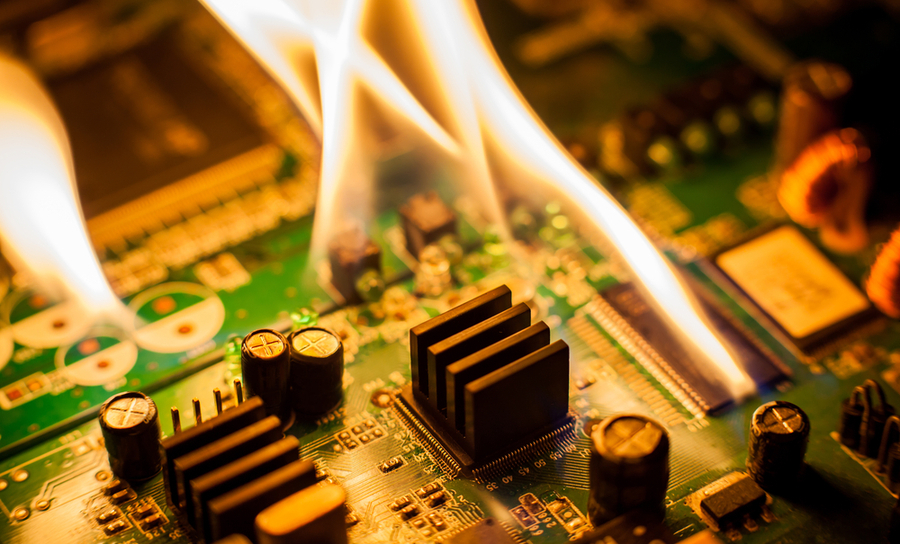

In PCB design, the same oversight of the temperature requirements of PCBs will cost you more than balloons and ice cream. You need to know how much heat your PCB can withstand before it

The three most common welding technologies in SMT processing are wave welding technology, reflow welding process, and laser reflow welding process. Below, the assypcb editor will explain these three welding processes in detail for

Choosing PCB Model and Quick-turn PCB Assembly services can help in reducing prices while ensuring your item reaches market promptly. These solutions will additionally assist you identify style and making issues prior to a

1. Rate reduction Conserving cash is a side benefit of using automated PCBA manufacturing. When constructing electronic circuits before manufacturing. Several surface install technology suppliers depend on proprietary modern technology. This is done to

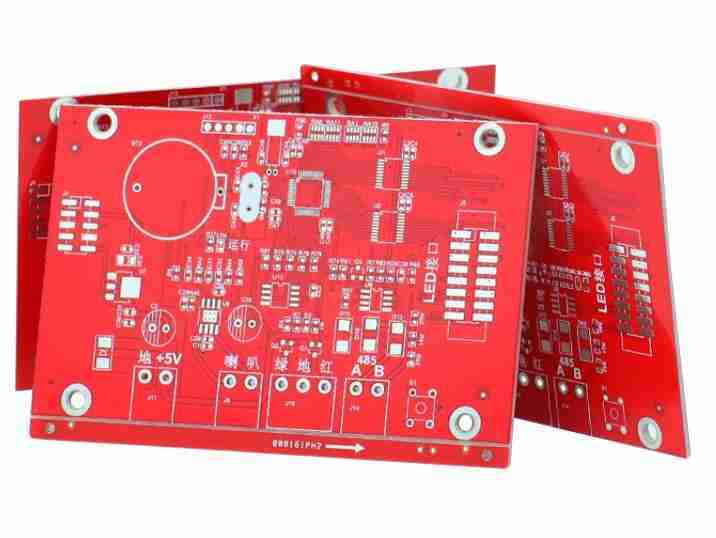

What are PCAs and PCBs Applications and Types? In most electronic products, a printed circuit board (PCB) is utilized as a base to sustain wiring and its outlet components installed on a surface area.

With various options for board layout, you no more need to choose using types and sizes without taking into consideration the impact on not the same elements of the layout and improvement process. Production