Printed Circuit Board Applications and Types

Table of Conent

Table of Conent

What are PCAs and PCBs Applications and Types?

In most electronic products, a printed circuit board (PCB) is utilized as a base to sustain wiring and its outlet components installed on a surface area.

In applications that call for great conductive electrical wiring, such as computer system systems, PCBs are produced using a photolithography procedure, which is a scaled-up variation of exactly how connections are produced in processors.

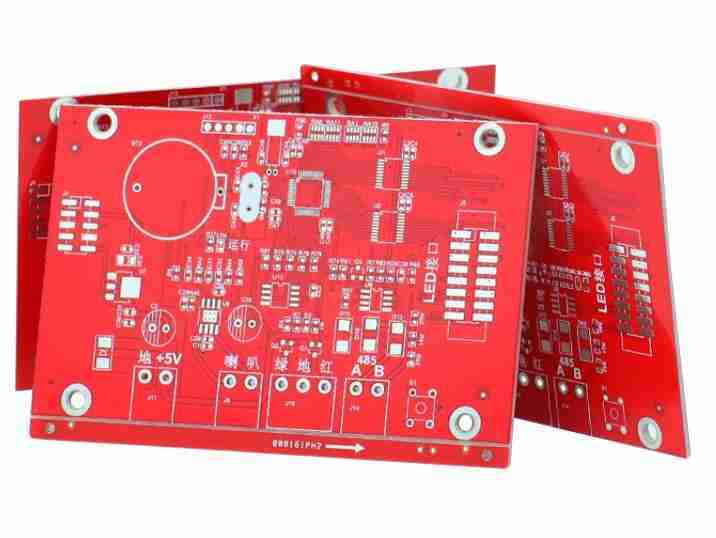

PCBs for basic digital tools are single-layer. Facility digital printed circuit card, such as motherboards and electronic graphics cards, can have up to twelve layers. PCBs are normally environment-friendly, but can likewise be tailored to any kind of shade.

Devices normally use solder to secure the digital devices to the completed suitable PCB. The PCB is baked in an industrial microwave to melt the solder that connects the elements. A lot of PCBs are comprised of fiberglass or glass-reinforced polymers with copper traces.

Unlike common cables, PCBs commonly link electrical elements with copper tracks. Drilled openings in the board are utilized to safeguard the electrical elements. They are soldered in position, and the copper tracks connect them to develop a circuit. The PCB and the components protected together are called a PCB assembly or PCA (published circuit assembly). Without this assembly process, the PCB is a board without feature, and its relevance is self-evident.

PCBs are present in mostly all digital tools we see and use daily. They are accountable for making numerous tools we use daily appearance smaller while containing more innovation. Its applications consist of:

• Televisions and radios

• Computers

• Alarm

• Coffee makers

• Washing equipments

• Video game gaming consoles

• Cellphone

• Stoves

Other application locations include military, clinical, and commercial parts (bikes, autos, planes, etc).

Review of PCB Manufacturing Process

It is vital to recognize the difference in between PCB manufacturing and its assembly process. PCB setting up manufacturing includes PCB design and prototyping procedures, while PCB assembly involves placing elements on published motherboard.

Now, we will certainly take a much deeper consider PCB manufacturing.

The 3 main processes of PCB manufacturing are board style, component procurement, and setting up. Whether the PCB setting up and manufacturing is for tiny or huge sets of PCBs, style for testability (DFT) and design for manufacturability (DFM) are crucial operations to make certain the maximum return within the job cost. Unlike manufacturing, the assembly of a particular PCB may differ depending on your choice or application.

Latest Blog

Contact Info

Phone: +86-755-82882936

Email: [email protected]

WhatsApp: +86-13570802455

Wechat: +86-13570802455

Address: 2nd floor,D Bldg.,Electric Link Technology Bldg.,Gongming,Guangming New Dist.,518106 Shenzhen, China