What Are the Advantages and Disadvantages of Single-Layer PCBs?

Table of Conent

Table of Conent

PCBs are made use of to sustain and connect electric parts in digital items. They are generally made from copper, material, and substrate. The performance and toughness of a PCB are directly associated with its dimension and variety of layers. Including more layers to a PCB enhances its functionality. This has significant benefits in the electronics market.

1. Single-layer PCB

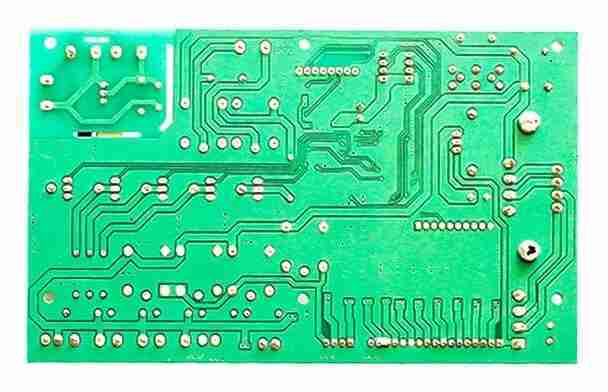

A single-layer published motherboard (PCB) is a form of circuit card that has just a thin covering of conductive product (generally copper) on one section of the board. The various other section works as a connection factor for numerous digital components.

Consequently, electrical limits, loads, connectors, components, cords, placing holes, vias, and pads are all manufactured utilizing a single-layer PCB substratum, a conductive metal layer, a silk screen, and a protective solder mask.

Regardless of the advent of advanced technologies, the electronics sector still counts greatly on single-layer PCBs.

2. Advantages of single-sided boards

Inexpensive of SMT production

Less complicated to develop and much less vulnerable to mistakes

Due to the fact that there is just one layer, soldering, placing, and electronic boring parts are simple.

Great selection for minimalist formats

Economical for mass production of consumer electronics

Ideal choice for quick, automation.

3. Disadvantages of Single-Layer PCBs

The advantages of single-layer PCBs are that they are easy and economical to produce. However they also have some negative aspects that individuals ought to recognize.

Absence of space and pins for links on printed circuit card where several components are required.

Reduced speed and performance.

As performance boosts, weight and size additionally enhance, decreasing the transportability of the tool.

Latest Blog

Contact Info

Phone: +86-755-82882936

Email: [email protected]

WhatsApp: +86-13570802455

Wechat: +86-13570802455

Address: 2nd floor,D Bldg.,Electric Link Technology Bldg.,Gongming,Guangming New Dist.,518106 Shenzhen, China