What Are the Types of PCB Surface Treatment Processes?

Table of Conent

Table of Conent

With the fast development of modern electronic information technology, PCB production technology has actually additionally transformed significantly, and the demands for item modern technology are obtaining higher and higher. Just like the motherboard in smart phones and computers now, some usage gold and copper, which makes the benefits and disadvantages of circuit boards much more noticeable.

Top quality PCB aids everyone to recognize the surface area innovation on printed circuit boards and contrasts the benefits and downsides of different PCB surface therapy processes and relevant scenarios.

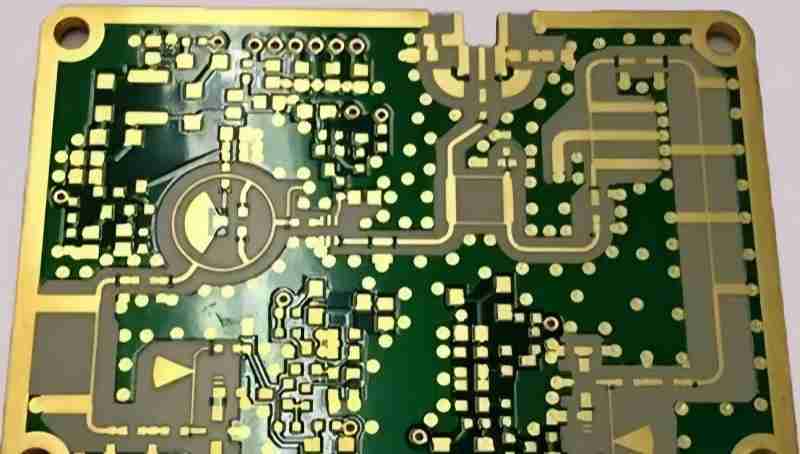

From the appearance of the board processed by PCB, its appearance generally has three colors: gold-silver-light red. Relating to classification, gold is the most pricey, silver is 2nd, and the cheapest is light red. It is very easy to see from the look whether the maker has actually reduced corners. The parts of the circuit board are generally pure copper, described as bare copper board.

1. The benefit of bare copper board is that the cost is reasonably low, the surface area is level, and its weldability is better without oxidation. Yet beware not to be affected by acid and temperature level. Copper is very easy to oxidize in the air after being placed for a very long time.

2. The gold on the immersion gold board is gold. Even if just a thin layer of conductor is plated, the cost of this has actually accounted for 10% of the expense of the whole circuit card. After immersion in gold therapy, it is difficult to oxidize, can be saved for a very long time, and has a smoother surface area. It appropriates for welding some fine-gap pins and some gadgets with smaller sized solder joints, such as smart phone boards. Its price is relatively high and the welding toughness is reasonably bad.

3. The tin-spraying circuit card is silver. It sprays a layer of tin outside of the copper circuit. It can help with welding, yet it can not have the very same lasting call integrity as gold. It is easy to oxidize and rust if made use of for a very long time, leading to poor get in touch with. It is frequently made use of on the circuit boards of some tiny digital products, and its cost is cheap.

4. In the SMT manufacturing facility, the OSP procedure board is also called natural change film. Because it is an organic compound, not a steel product, it is cheaper than the tin-spraying procedure.

It has all the benefits of bare copper plate welding. Even expired circuit card can be dealt with again on the surface, but they are conveniently affected by acid and moisture. If the storage time is also long, greater than 3 months, the surface area treatment have to be done again. OSP is a protecting layer, so the test point needs to be published with solder paste to remove the original OSP layer prior to the pinpoint can be spoken to for electrical testing.

Latest Blog

Contact Info

Phone: +86-755-82882936

Email: [email protected]

WhatsApp: +86-13570802455

Wechat: +86-13570802455

Address: 2nd floor,D Bldg.,Electric Link Technology Bldg.,Gongming,Guangming New Dist.,518106 Shenzhen, China