What Is the PCB Manufacturing Process Like?

Table of Conent

Table of Conent

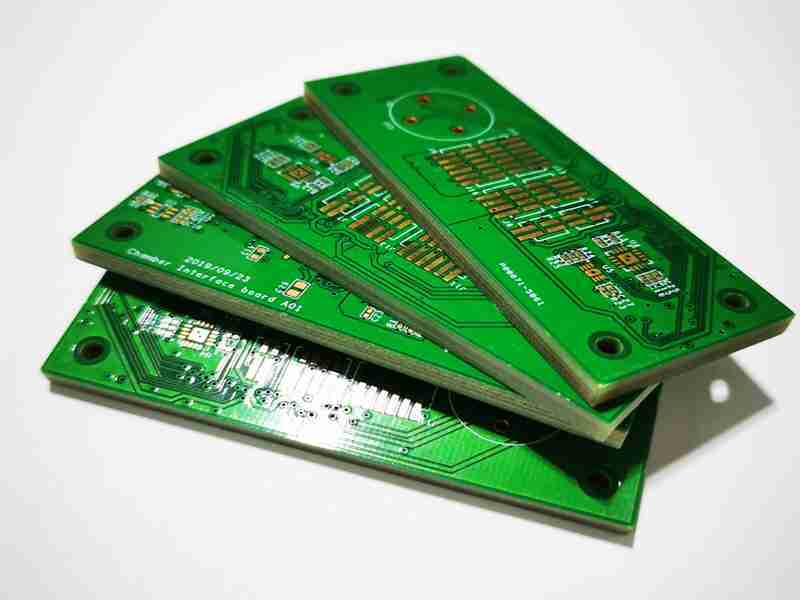

Top quality PCB establishes minimum standards for circuit board production and setting up. It includes three performance classifications based on parameters and specifications for procedure and reliability assumptions. Nonetheless, for all groups, PCB production consists of the complying with actions.

Step 1, Imaging The first step in PCB manufacturing is to create an image of the circuit. It is for not just the leading and bottom layers of the board but additionally the internal layers of the stack for a multi-layer design. The copper layer is covered with photoresist and revealed to light.

Step 2, Etching (Inner Layers) Etching is the procedure of getting rid of copper from all locations other than traces or various other conductor points. Ammonia-based services are usually used.

Step 3, Stacking For this step, the motherboard layers (substratum and laminate) are piled, straightened, and heat-pressed together.

Step 4, Exploration With openings and mounting openings are drilled through these layers. It is very important to adhere to the appropriate boring process right here and follow element proportion restrictions.

Step 5, Etching (Outer Layers) For the outer layers, the photoresist and excess copper should be eliminated.

Step 6, PCB Plating Exploration holes with copper plating enable existing flow between layers.

Step 7, Solder Mask A Solder mask is a polymer movie, normally eco-friendly, black, red, yellow, or white, that protects non-conductive surface.

Step 8, Silk Display Application This is where tags, polarity symbols, pin one indicators, and various other information are published externally of boards. These are normally applied by an inkjet printer.

Step 9, Include Surface Finish The main function of surface area finish is to secure copper locations from environmental risks, particularly wetness and oxidation.

PCB processing creates the bare board or PCB with no part, which must not be perplexed with PCB assembly (PCBA), where parts soldering onto the board. The beginning of PCBA manufacturing rely greatly on centimeters procedures and tools. However, the design selections you make aid determine whether your board is made optimally.

Latest Blog

Contact Info

Phone: +86-755-82882936

Email: [email protected]

WhatsApp: +86-13570802455

Wechat: +86-13570802455

Address: 2nd floor,D Bldg.,Electric Link Technology Bldg.,Gongming,Guangming New Dist.,518106 Shenzhen, China