Accessories

1. Capacitors Overview

Functional Positioning: Auxiliary accessories of capacitors are mainly used to install, protect, or optimize the performance of capacitors in circuits, including physical fixation, heat dissipation management, electrical connection, etc.

Necessity: Capacitors must meet requirements such as stability and durability in circuits, and accessories can enhance their ability to adapt to complex environments (such as high temperature and vibration).

2. What are the Common Types of Capacitors?

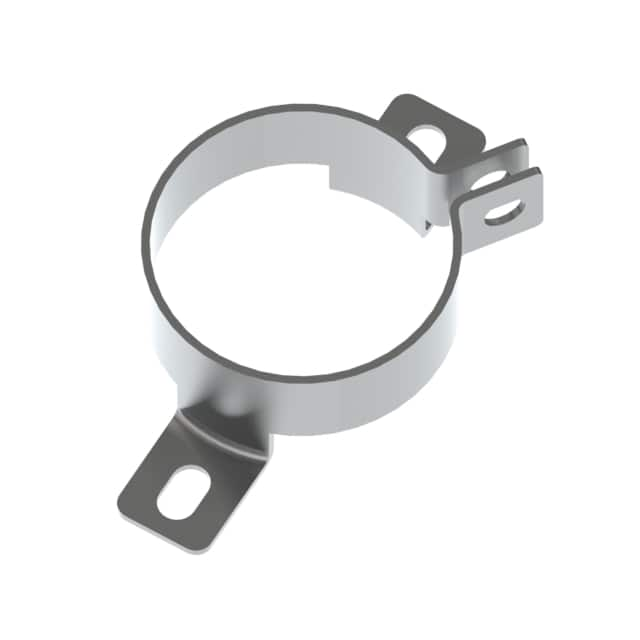

1) Installation and Fixing Type

Bracket/Fixing Clip: Ensure that the capacitor is firmly installed in the circuit board or equipment to avoid physical displacement.

Insulation Sleeve/Sheath: Prevent the capacitor plate from contacting the external conductor and reduce the risk of short circuits.

2) Connection and Interface Type

Terminal/Connector: Provide reliable electrical connection between the capacitor and the circuit, and need to adapt to different packaging types (such as plug-in type, surface mount type).

Jumper/Lead: Used to adjust the position or connection method of the capacitor to adapt to a specific circuit layout.

3) Performance Optimization Category

Heat Sink: Improve heat dissipation efficiency for heating problems of capacitors in high-power or high-frequency applications.

Damper/Shock Pad: Reduce the impact of mechanical vibration on the internal structure of the capacitor and extend its service life.

3. Selection and Application of Capacitors

Matchability: Select matching accessories according to the type of capacitor (such as electrolytic capacitors and ceramic capacitors) and the working environment.

Industrial Field: In power systems, communication equipment, automotive electronics, and other scenarios, accessories are crucial to the stable operation of capacitors.

4. Precautions for Using Capacitors

Electrical Parameters: Connection accessories must meet the voltage, current, and frequency requirements of the capacitor to avoid introducing additional impedance or loss.

Material Compatibility: Accessory materials (such as plastics and metals) should be compatible with the operating temperature and dielectric properties of the capacitor.

Through the above accessories, the reliability, safety, and applicability of the capacitor can be comprehensively improved to meet the needs of diversified electronic systems.