Backplane Connectors

As a key component in the field of electronic components, backplane connectors play the core circuit connection and signal transmission functions in complex electronic devices.

1. What are Backplane Connectors?

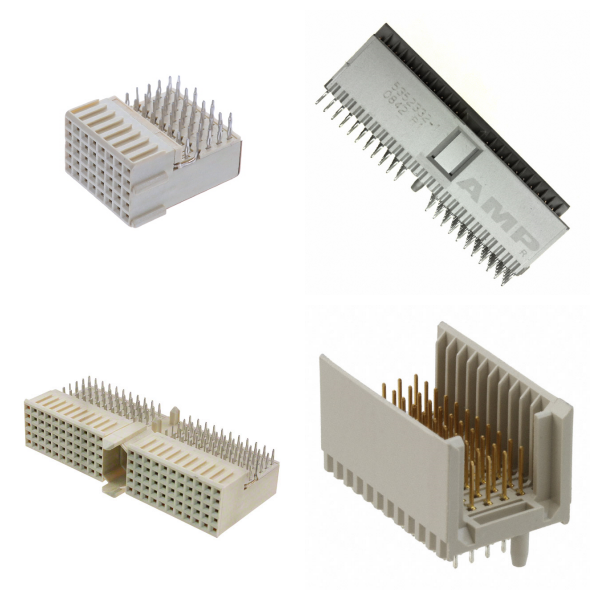

Backplane connectors are vertical structure connectors used to connect daughter cards to backplanes, usually in a 90-degree orthogonal layout to achieve high-speed signal transmission between circuit boards. Its core functions include:

High-speed Signal Transmission: Supports differential signal or single-end signal transmission, with a rate of up to 25 Gbps to 224 Gbps;

High Current Carrying: Provides stable power support for high-performance servers, communication equipment, etc.;

Modular Expansion: Simplifies the complexity of the internal layout of equipment through flexible structural design (such as board-to-board, board-to-cable, etc.).

2. What are the Types of Backplane Connectors?

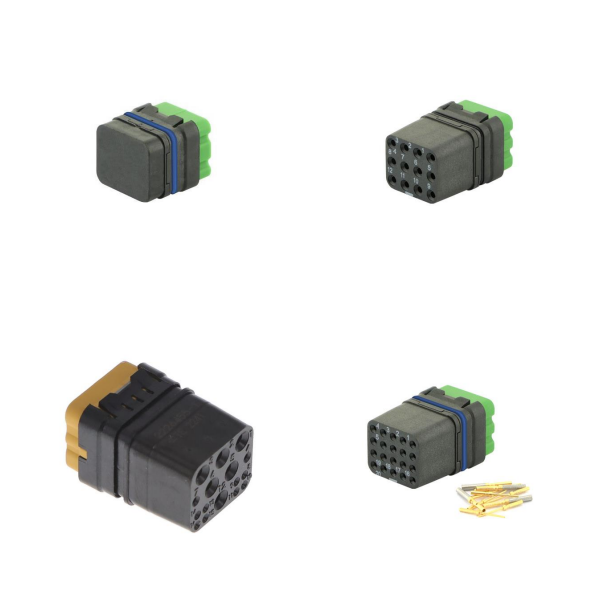

Backplane connectors are mainly divided into four categories according to their structure:

180° board-to-board (Backplane): suitable for high-density connection scenarios;

90° orthogonal board-to-board (Orthogonal): saves space and is often used in compact devices;

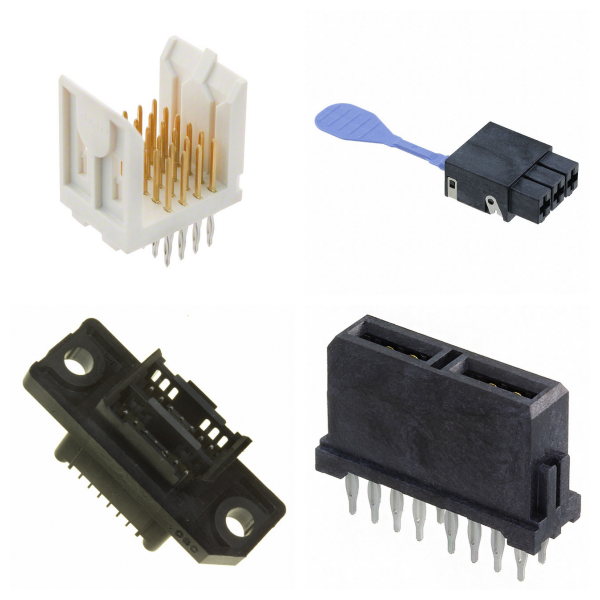

Board-to-Cable: connects circuit boards with external cables;

Cable-to-Cable: directly connects two cables.

Some special scenarios also support floating installation design, allowing ±0.2mm displacement to meet blind plug requirements.

3. Technology Evolution and Industry Standards of Backplane Connectors

With the surge in bandwidth demand for AI servers and data centers, the transmission rate of backplane connectors continues to break through:

Rate Development: International leading manufacturers (such as Amphenol and Molex) have mass-produced 224Gbps products, supporting 67GHz bandwidth;

Technical Solution: Use PAM4 modulation technology to optimize signal integrity, and reduce PCB routing loss through near-chip installation (Near-chip) or overpass on chip bridging (Overpass on chip);

Industry Standards: Although there is a lack of unified specifications, Amphenol’s technical parameters are often used as an industry reference.

4. What are Backplane Connectors Used for?

Backplane connectors are widely used in scenarios with strict requirements on stability and transmission efficiency:

AI Servers and Supercomputing: support massive data interaction between GPU clusters;

Communication Base Stations and Industrial Equipment: ensure the reliability of high-speed signal transmission;

High-end Storage Systems: achieve multi-module collaborative operation.

5. What are the Installation Methods of Backplane Connectors?

Depending on the equipment requirements, a variety of installation options can be used:

Fixed Installation: fixed to the panel by screws (front/back installation);

Printed Board Installation: directly integrated into the PCB board;

Crimp Installation: use fisheye terminals to achieve conductive connection.

As the “super artery” of data transmission, the high-frequency performance and structural design of the backplane connector continue to promote the evolution of electronic devices to higher integration and efficiency. With the popularization of AI and cloud computing technologies, its market size is expected to maintain rapid growth.