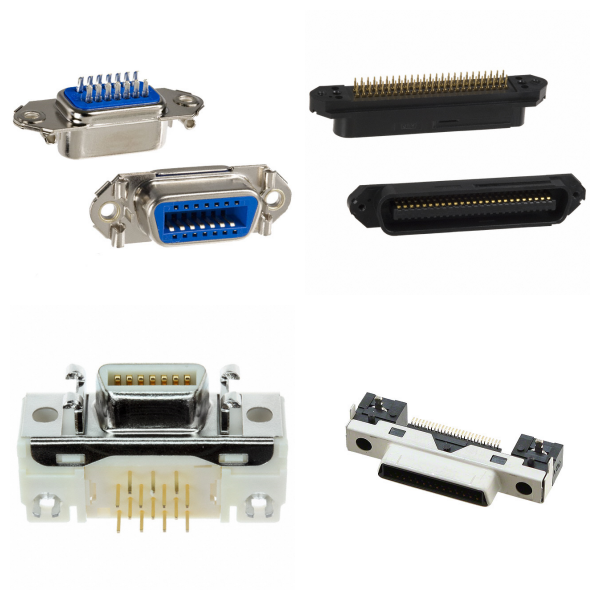

D-Sub, D-Shaped Connectors

D-Sub (D-shaped) connector is a classic electronic interconnection solution, and its name comes from the unique D-shaped metal shield profile.

1. D-Sub, D-Shaped Connectors Overview

Full Name: D-Subminiature Connector, first created by ITT Cannon in the United States in the 1950s.

Appearance Features: The shell is in the shape of the letter “D”, and the mechanical anti-misinsertion function is achieved through asymmetric design.

2. What is the Core Structure of D-Sub, D-Shaped Connectors?

Shell Material: The metal shell provides electromagnetic shielding and mechanical protection, and some models use plastic shells to reduce costs.

Contact Design: It includes two types: male head (pins) and female head (holes), supporting differential signal transmission to reduce electromagnetic interference.

Pin Density: It was known for its ultra-small size in the early days, and now high-density models have been developed to meet complex wiring needs.

3. Technology Evolution of D-Sub, D-Shaped Connectors

First Generation (1960s)

The double-layer protection structure (metal shell + plastic body) adapts to the harsh environment of aviation and military fields.

Second Generation (mid-1980s)

Stamping technology replaced lathe processing, significantly reducing manufacturing costs and promoting the popularization of computer peripherals.

Third Generation (1990s to Present)

The simplified structure is a single-layer shell, and the models are expanded to DA/DB/DC series to meet the needs of industrial control and medical equipment.

4. Specifications and Applications of D-Sub, D-Shaped Connectors

|

Category |

Typical Specifications |

Main Application Scenarios |

|

Standard |

9-pin, 15-pin, 25-pin |

RS-232 serial port, VGA video interface |

|

High-density |

37-pin and above |

Industrial automation, high-speed data transmission |

|

Hybrid |

High-low frequency composite design |

Aerospace equipment, precision instruments |

5. What are the Key Advantages of D-Sub, D-Shaped Connectors?

Stability: Gold-plated contacts and a multi-point grounding design ensure signal integrity.

Compatibility: Standardized interfaces support cross-generation device interconnection.

Durability: It can withstand more than 500 plug-in and unplug cycles, suitable for frequent maintenance scenarios.

With its modular design, this connector continues to play a key role in industrial control, medical equipment, and communication infrastructure.

6. D-Sub, D-Shaped Connectors FAQs

1) What is the origin of the name D-Sub?

D-Sub stands for “D-Subminiature” and is named for its unique D-shaped shielding cover design. In the early days, it was called an “ultra-miniature” connector because of its miniaturization. Although the volume advantage is no longer prominent, the D-shaped structure still effectively prevents mis-insertion.

2) What are the main application areas of D-Sub connectors?

Computer and Communication Equipment: such as VGA interface, serial port;

Industrial and Military: vibration-resistant design is suitable for aerospace and defense equipment;

Power and Signal Transmission: supports analog, digital, and power signals.

3) What is the difference between high-density D-Sub and standard D-Sub?

High-density D-Sub increases the pin density under the same shell size (such as DB25 shell can accommodate a higher number of pins), which is suitable for compact space requirements, while the standard version has a sparser pin arrangement.

4) How does D-Sub achieve electromagnetic interference (EMI) protection?

Through metal shell shielding and additional EMI filtering design (such as a Pi-type adapter), it is suitable for sensitive electronic environments.

5) What are the typical installation methods of D-Sub connectors?

Board End Installation: welding or direct plug-in PCB installation;

Cable Assembly: injection molding (non-removable) and assembly (removable metal/plastic back shell);

Screw Fixing: ensure a stable connection to prevent accidental detachment.

6) What are the special uses of combined D-Sub connectors?

Combined D-Sub integrates different types of interfaces (such as power + signal) in the same shell, reducing the complexity of the wiring harness and reducing the risk of signal interference.

7) What scenarios are micro D-Sub (Micro-D) suitable for?

Designed for extreme environments (such as aerospace equipment), it is smaller and has a wide temperature range (-55°C to 125°C), suitable for high-density electronic devices.

8) How does the material selection of the D-Sub connector affect its performance?

Metal Housing: Improves shielding and mechanical strength;

Lightweight Aluminum Backshell: For aerospace scenarios where weight reduction is required;

Plastic Insulator: Balances cost and basic protection needs.

9) How is the maintenance and reliability of D-Sub connectors?

The pin and socket contact design supports on-site repairs, and the metal structure ensures long life (especially in vibration environments). Some models have a protection level of IP68 and are suitable for humid or dusty environments.