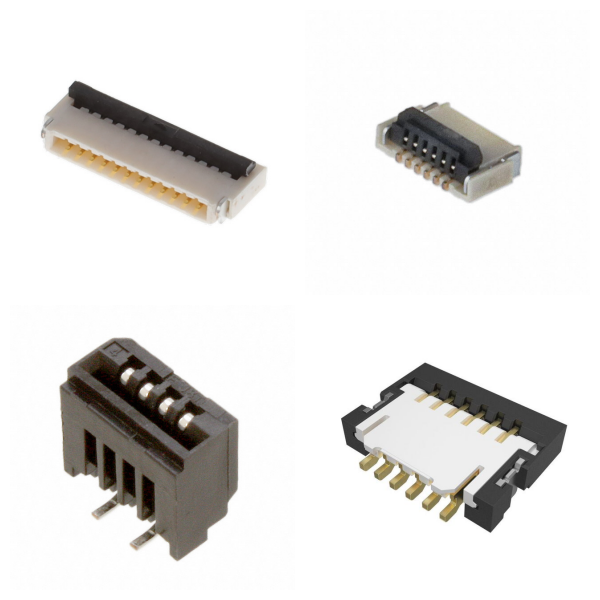

FFC, FPC (Flat Flexible) Connectors

FFC/FPC (Flat Flexible) connectors are interconnection components designed for flexible flat cables (FFC) and flexible printed circuit boards (FPC), playing a key role in the miniaturization and high-density integration of electronic devices.

1. What are FFC, FPC (Flat Flexible) Connectors?

1) Definition

FFC Connector: used to connect ribbon flat flexible cables (FFC) to PCBs or other components, usually with a high-density narrow design to fit into small spaces.

FPC Connector: designed for flexible circuit boards (FPCs), one end is fixed to the PCB by SMT soldering, and the other end is plugged into the FPC, with a built-in locking device to ensure contact reliability.

Both are made of PET insulating material or polyimide as the base material, and are made by the tinned copper wire pressing or printing process.

2) Core Structure

Includes copper foil substrate (electrolytic copper/rolled copper), cover film (insulating layer), adhesive, and reinforcement plate (to enhance mechanical strength), etc.

FPC connectors must meet strict coplanarity requirements (≤0.10mm) to ensure welding quality.

2. What are the Advantages of FFC, FPC (Flat Flexible) Connectors?

Flexibility

Supports bending and folding, adapts to complex spatial layout, and bending radius control can extend service life.

High density and lightweight

Flat design realizes multi-wire integration, reduces volume and weight, and is suitable for lightweight needs such as mobile devices.

Reliability

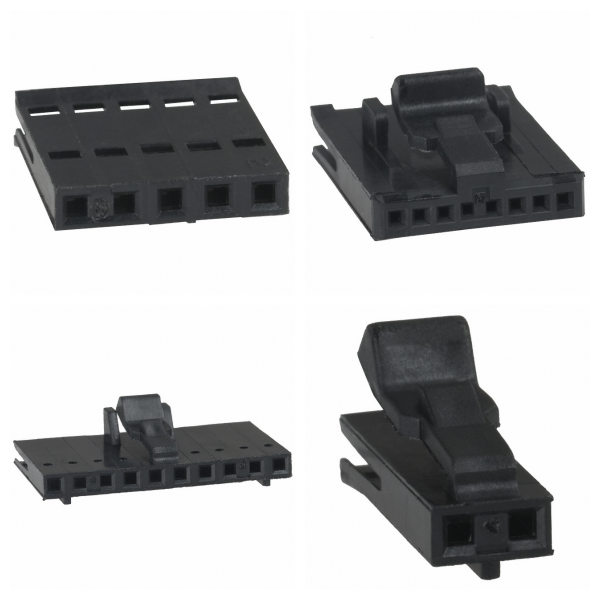

Excellent vibration and impact resistance, and the locking structure enhances plug-in stability.

Signal integrity

Optimize conductor spacing and shielding design to reduce electromagnetic interference (EMI).

3. What are FFC, FPC (Flat Flexible) Connectors Used for?

|

Field |

Application scenario |

|

Consumer electronics |

Smartphone display connection, camera module, wearable device internal wiring |

|

Automotive electronics |

Car navigation system, sensor signal transmission, and entertainment equipment interconnection |

|

Industrial and medical equipment |

Precision instrument control board connection, medical monitoring equipment data transmission |

|

Computer and peripherals |

Printer head and motherboard connection, laptop internal high-speed signal transmission |

4. Design and Use Precautions for FFC, FPC (Flat Flexible) Connectors

Installation Process

FFC mostly uses plug-in connectors for easy maintenance; FPC requires precision welding, and the coplanarity of solder joints needs to be controlled.

The welding temperature needs to be adapted to the heat resistance of the material (e.g., polyimide can withstand higher temperatures).

Parameter Matching

The conductor pitch (Pitch) is commonly 0.3mm and 0.5mm, which needs to be selected according to the signal frequency.

The total length (TL), margin (M), etc., need to meet the equipment space limitations.

Durability Design

Avoid excessive bending (the recommended minimum bending radius is ≥3 times the thickness of the cable).

The plug-in life needs to meet the application scenario requirements (e.g., industrial equipment needs ≥10,000 times).

5. The Difference between FFC and FPC Connectors

|

Features |

FFC Connector |

FPC Connector |

|

Structural Complexity |

Simple parallel conductor arrangement, single-layer insulation |

Multi-layer printed circuit, including shielding layer and reinforcement board |

|

Cost |

Low, suitable for mass production |

High, adapt to complex circuit requirements |

|

Typical Applications |

Printers, home appliance signal transmission |

High-frequency signal equipment (such as camera modules) |

FFC/FPC connectors have become one of the core components of miniaturization and high performance of modern electronic devices through their unique flexible design and adaptability.