Heavy Duty Connectors

Heavy Duty Connectors are high-performance electronic connectors designed for harsh industrial environments. Their core function is to provide a stable and reliable interface for power, signal and data transmission.

1. What are Heavy Duty Connectors?

Definition: Heavy-duty connectors are electrical connectors designed for high current, high voltage, and harsh industrial environments, with high durability and reliability.

Alias: Also known as industrial connectors or industrial sockets, they are commonly used in power transmission, signal control, and other fields.

2. What are the Core Features of Heavy Duty Connectors?

High Environmental Adaptability

Using metal or engineering plastic shells, they have impact resistance, vibration resistance and corrosion resistance, and are suitable for harsh conditions such as high temperature, high humidity, and dust.

The protection level can reach IP65/IP67, which is effectively waterproof and dustproof, and some models support explosion-proof requirements.

High-performance Electrical Parameters

Support high current (up to hundreds of amperes) and high voltage transmission to meet the needs of heavy machinery and industrial equipment.

The terminals are designed with screw or crimp connection to ensure low contact resistance and long-term stability.

Modularity and Flexibility

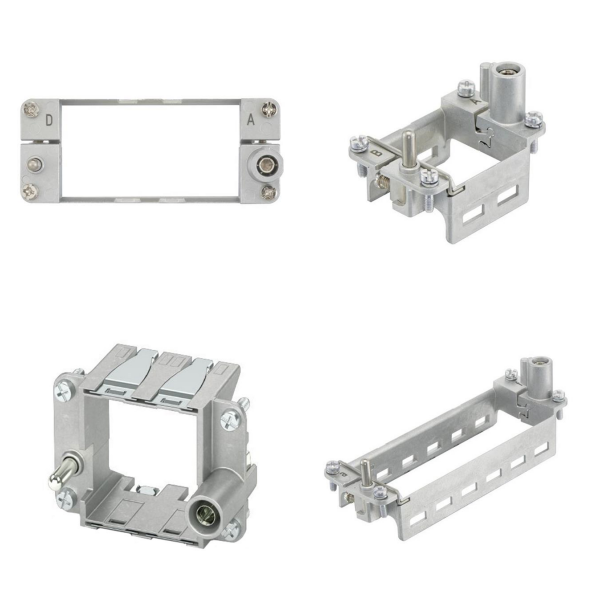

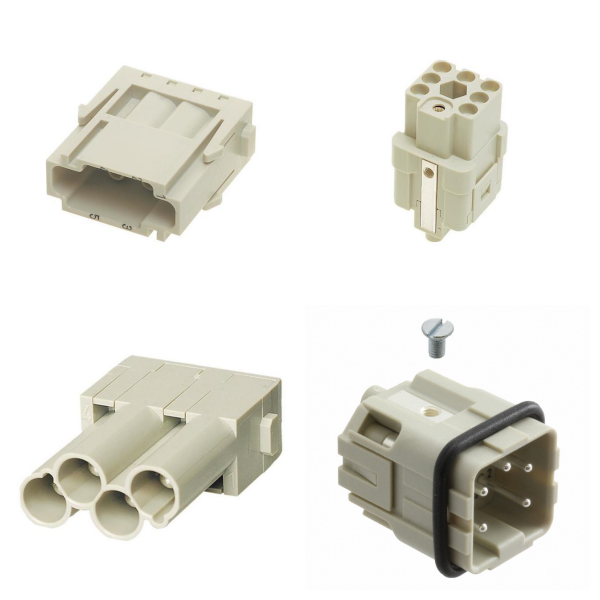

The structure is divided into three parts: terminal system, shield/housing, and insert, which supports the combination of signal, power, or pneumatic modules on demand.

Supports quick plug-in and locking mechanisms (such as snaps, threads, or rotary bayonet) to simplify installation and maintenance processes.

Enhanced Safety

Built-in anti-misplug design to avoid the risk of a short circuit caused by incorrect polarity or direction.

Some models integrate overload protection and electromagnetic shielding functions to improve the overall reliability of the system.

3. What are Heavy Duty Connectors Used for?

Industrial Automation: power and signal connection of robots, PLC control boxes, and automated production lines.

Energy and Transportation: high-voltage power distribution of wind power equipment and rail transit on-board systems.

Infrastructure: weather-resistant connection of construction machinery, port equipment, and outdoor lighting systems.

Data and Communication: high-speed data, video, and audio transmission scenarios (such as industrial Internet of Things).

4. Technology Evolution of Heavy Duty Connectors

Phoenix Contact HEAVYCON Series

Provides metal/plastic housing, multiple locking types, and modular contacts, supporting direct installation and customized configuration.

Molex GWconnect Series

Adopts die-cast aluminum housing and a standardized interface, suitable for a high-load mechanical environment.

Development Trend

Evolves towards integration (power + signal + data mixed transmission) and lightweight design, while being compatible with emerging protocols such as industrial Ethernet.

5. Selection Suggestions for Heavy Duty Connectors

It is necessary to comprehensively consider the current/voltage requirements, protection level, installation method (such as side outlet or straight outlet), and environmental tolerance (such as chemical corrosion or extreme temperature). Manufacturers usually provide adapter accessories (such as cable glands, covers) to expand application scenarios.

Electrical Parameters: Match the model according to the voltage and current requirements (such as HEF-0.75 series).

Environmental Adaptability: Consider the temperature range, protection level, and chemical corrosion resistance.

Interface Type: Whether Ethernet or other data transmission functions need to be integrated.

6. Heavy Duty Connectors FAQs

1) What are the precautions for installation and maintenance of Heavy Duty Connectors?

Installation Specifications: Ensure pin alignment and avoid excessive bending of cables.

Regular Inspection: Clean contact points and check seal integrity to prevent oxidation or corrosion.

Technical Support: Some manufacturers provide customized solutions and technical support (such as TE Connectivity).

2) What are the differences between Heavy Duty Connectors and other connectors?

Compared with ordinary connectors, heavy-duty connectors have significantly improved load capacity, protection level and durability, and are suitable for harsh industrial environments.

Some models integrate hybrid functions (such as Ethernet + power), reducing system complexity.