What Should I Do If the PCB Pad Is Welded Off?

Table of Conent

Table of Conent

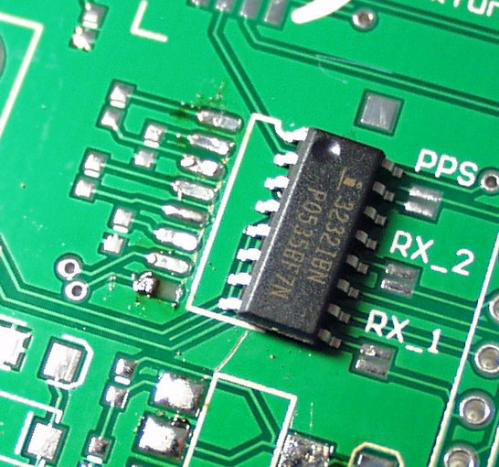

During the welding process, the PCB pad often falls off due to long welding time or multiple weldings leading to high temperature, which causes the pad copper sheet to expand repeatedly and fall off. Therefore, special attention should be paid during welding to avoid further falling off. Please refer to the demonstration picture below, where the circled part represents the pad point where the pad has fallen off.

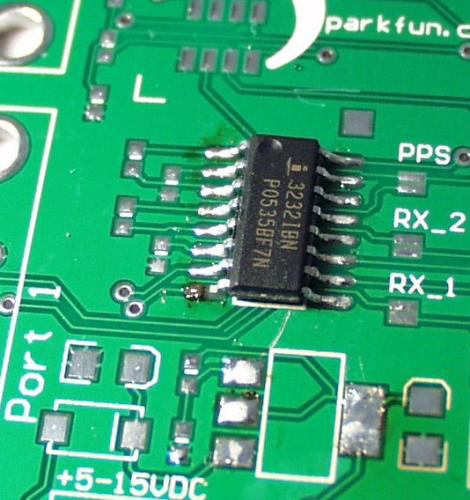

In this case, you can see a path starting from where the pad was previously, and its connection point to the through hole. Since the pad is no longer there, you can jump directly from the through hole to the pin of the integrated circuit to reestablish the electrical connection.

Bridging, if there are other components on the same circuit around the pin of the dewelded pad component, you can weld the component pin directly to the pin of the component, thereby discarding the original pad.

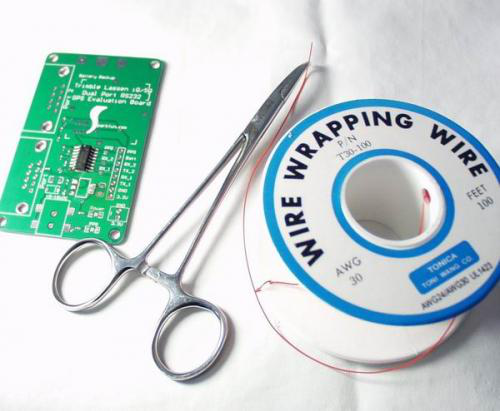

Shenzhen Assypcb SMT: This is a 30AWG wire wrap.

Latest Blog

Contact Info

Phone: +86-755-82882936

Email: [email protected]

WhatsApp: +86-13570802455

Wechat: +86-13570802455

Address: 2nd floor,D Bldg.,Electric Link Technology Bldg.,Gongming,Guangming New Dist.,518106 Shenzhen, China