PCBA Vacuum Packaging Machine Operating Specifications

Table of Conent

Table of Conent

1.Purpose:

The operator can use the VS-600 pneumatic packaging machine correctly to avoid improper operation that may affect product quality, cause machine failure, or cause personal injury.

2.Scope:

All humidity-sensitive components (PCB, IC, BGA, QFP) packaging of the company.

3.Job content:

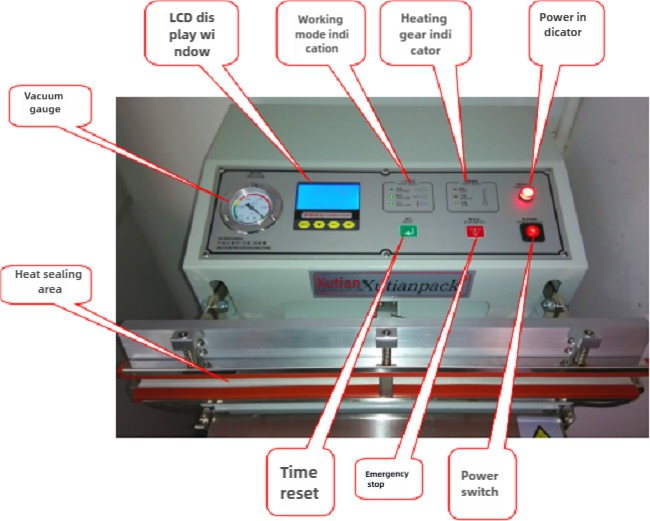

3.1 Introduction to the operation panel:

3.2 Parameter setting:

3.2.1 Set the heating and cooling time according to the selected plastic bag material and thickness.

3.2.2 Set the vacuum time according to the size of the packaged plastic bag.

3.2.3 Select the working mode as needed: sealing, vacuum, inflation.

3.3 Operation steps:

3.3.1 Connect the socket of the vacuum packaging machine to the power supply and turn on the power switch.

3.3.2 Set the parameters of the machine according to the product packaging needs and ensure that the machine enters the standby state.

3.3.3 Place the plastic bag in the sealing position, place the vacuum nozzle in the bag mouth, and place the packaging element about 2cm away from the vacuum nozzle.

3.3.4 Pull the bag mouth to both sides by hand to avoid wrinkles, and ensure the bag mouth is placed on the heating plate.

3.3.5 Press the foot switch again, and the machine will automatically complete the vacuuming, sealing, and cooling functions according to the set program. The vacuum gauge pressure is set at 0.4-0.6MPa

3.3.6 After packaging, pick up the material for inspection to confirm that the air in the packaging bag is evacuated, the seal is intact, and it is in a vacuum state. (As shown below)

4.Precautions:

4.1 During normal operation, be careful not to put your hands under the pressure rod to prevent accidental touching of the foot switch and causing injury.

4.2 After packaging, do not touch the packaging strip (be careful of being burned due to high temperature).

4.3 If an emergency occurs during the processing operation, press the emergency button or turn off the power switch to reset the power.

Latest Blog

Contact Info

Phone: +86-755-82882936

Email: [email protected]

WhatsApp: +86-13570802455

Wechat: +86-13570802455

Address: 2nd floor,D Bldg.,Electric Link Technology Bldg.,Gongming,Guangming New Dist.,518106 Shenzhen, China