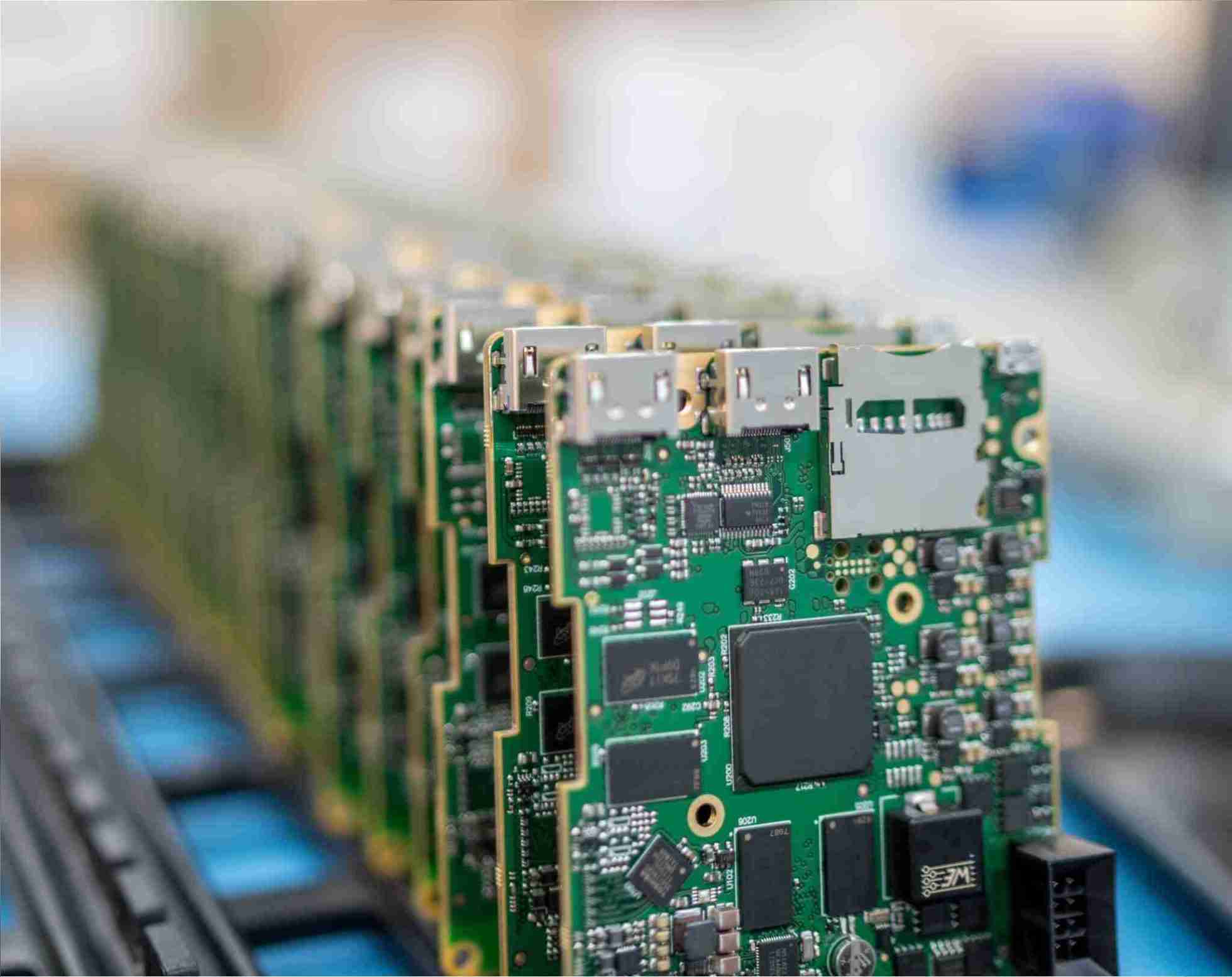

Surface Mount PCBs (Printed Circuit Boards) have revolutionized the design, manufacturing, and use of electronic devices. This compact, efficient solution has enabled the miniaturization of consumer and industrial products. From smart phones and laptops, to

PCB Assembly is the cornerstone of electronic devices. Chances are that a PCB powers your smartphone, laptop or tablet. This article dives into the fascinating world PCB Assembly and breaks down complex concepts in a

The PCB finish Nickel, also known as electrolytique soudabilite, improves solderability and protects copper surfaces. Nickel is used as a base to prevent corrosion for further surface treatments. Electrolytic finishes such as gold or tin

Modern electronics manufacturing owes a significant debt to the advancements in Automatic Test Equipment (ATE), which plays a pivotal role in ensuring the quality and efficiency of Printed Circuit Board Assemblies (PCBA). By integrating ATE

LED light bulbs frequently need to fade for various uses, including mood lighting, stage effects, and home automation. Creating a smooth fading effect requires understanding the basics and selecting the right technical components. The elements

The PCB is the main part of all modern electrical gadgets. Finding an affordable and dependable method for soldering components on the surface is crucial for small-scale producers and electronics enthusiasts. One popular DIY solution

In surface mount technology (SMT) printed circuit boards (PCBs), welding paste printing is crucial. Since welding paste directly determines the formation of welding joints, its printing quality has a decisive influence on the performance and

The production process of SMT processing is extremely complex, and each process is closely linked. Problems in any link will affect product quality. To enhance the quality of PCBA processing and soldering, professional testing equipment

In the wave welding machine, the larger the contact area between the molten welding and the air, the more tin oxide is generated. The size of the contact area is directly related to the opening

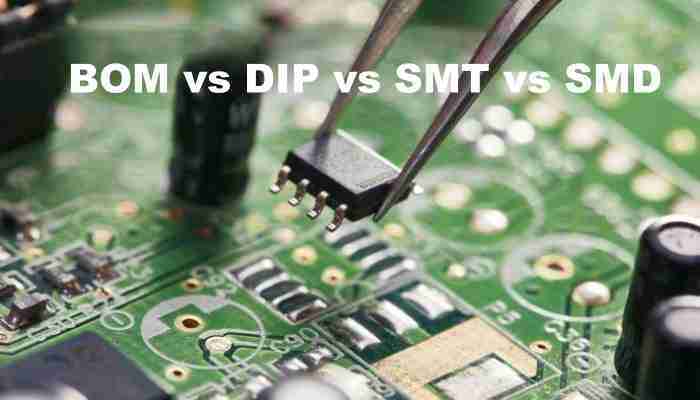

BOM table The Bill of Materials, or BOM (Bill of Material), is a document that describes the product structure in detail in the form of data. In the SMT processing process, BOM includes key information

Email us for a Free Quote: [email protected]