The production process of SMT processing is extremely complex, and each process is closely linked. Problems in any link will affect product quality. To enhance the quality of PCBA processing and soldering, professional testing equipment

In the wave welding machine, the larger the contact area between the molten welding and the air, the more tin oxide is generated. The size of the contact area is directly related to the opening

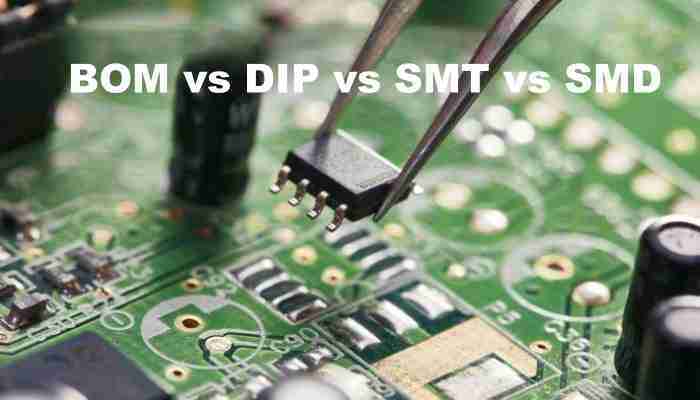

BOM table The Bill of Materials, or BOM (Bill of Material), is a document that describes the product structure in detail in the form of data. In the SMT processing process, BOM includes key information

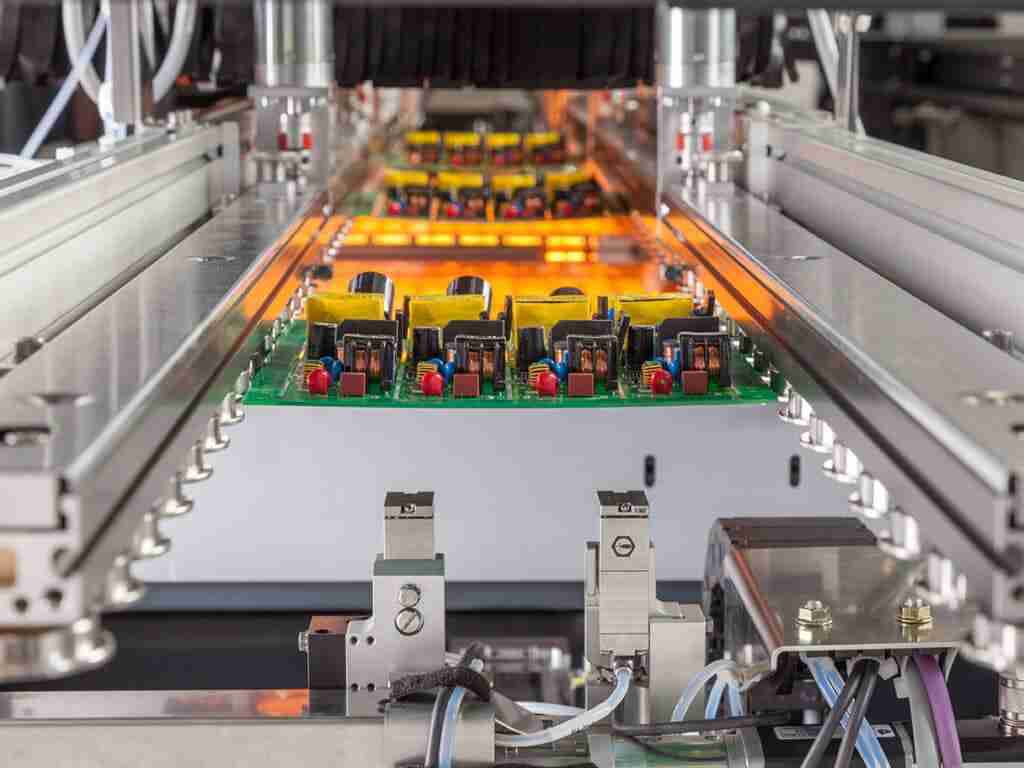

The core processes of SMT processing include solder paste printing, SMT machine operation, and reflow soldering. Only by effectively controlling the SMT process flow can we ensure the excellence of processing quality and improve

1.Purpose: The operator can use the VS-600 pneumatic packaging machine correctly to avoid improper operation that may affect product quality, cause machine failure, or cause personal injury. 2.Scope: All humidity-sensitive components (PCB, IC, BGA, QFP)

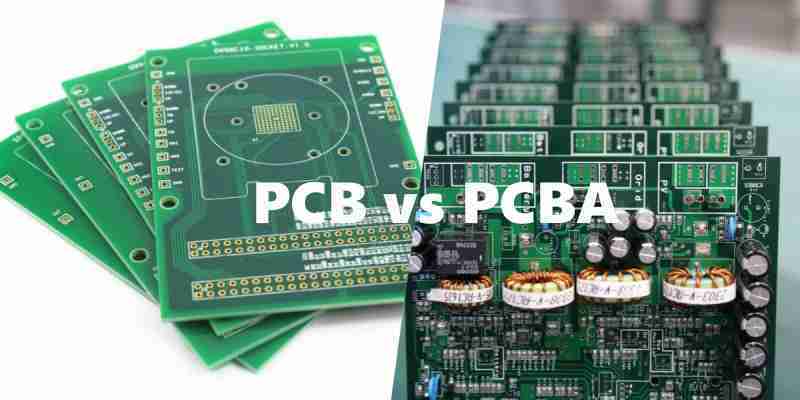

With the rapid development of electronic information technology, I believe many people have heard of the two professional terms "PCB" and "PCBA" and are not unfamiliar with them. After an in-depth discussion, we found that

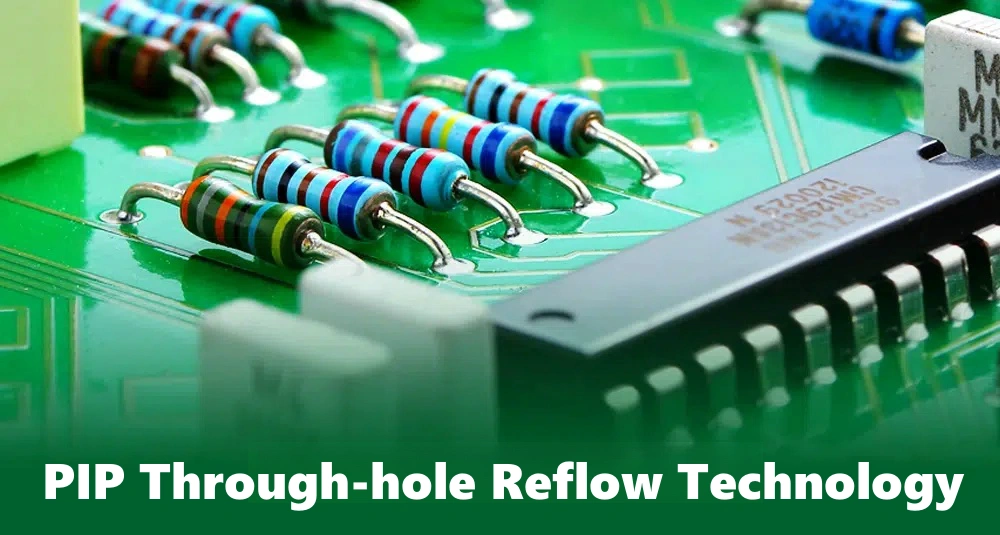

PIP technology is a method of assembling through-hole components using a standard reflow welding process. This process is also called THTR (Through-hole Technology Reflow). In most printed circuit boards (PCBs) containing surface mount components

During my electronics career, I have been exposed to and used many welding techniques. Initially, I relied mainly on welding irons for welding work. Almost all welding tasks can be completed with a welding iron.

PCBA experts know the main benefits of automating the SMT device assembly process: reduced errors, increased yields, and consistent quality, but is automation always better? The use of SMT production line machines has become

Manual Welding In many aspects, manual welding has become almost an obsolete technique as more precise and reliable processes have been created. While hand welding was once a great technique, it has gradually declined

Email us for a Free Quote: [email protected]